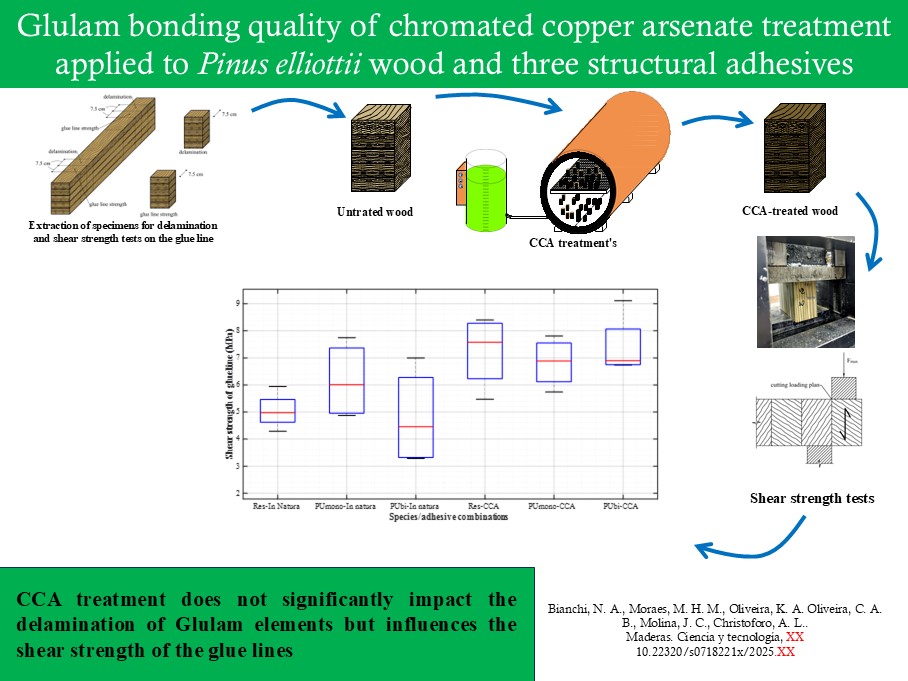

Glulam bonding quality of chromated copper arsenate treatment applied to Pinus elliottii wood and three structural adhesives

DOI:

https://doi.org/10.22320/s0718221x/2025.21Keywords:

Adhesive bonding, Chromated Copper Arsenate, delamination, Glued Laminated Timber, Glue line shear, Pinus elliottii, preservative treatmentAbstract

Glued laminated timber is an alternative gaining prominence in the Brazilian construction field. As a result, industries seek ways to improve the quality of their products, focusing on the wood used, the adhesive, and the manufacturing process. The aims of this study are to evaluate the effect of the preservative treatment chromated copper arsenate (CCA) as a preservative treatment on the gluing quality of Pinus elliottii (slash pine) glued laminated timber (Glulam) elements. For this purpose, Glulam was compared with and without CCA treatment, using Cascophen RS 216 -M, Jowat 686,60 and AG 101 adhesives to bond the laminated wood specimens. The glue quality was evaluated through delamination and shear strength tests of the glue lines based on the test method, following the European standard. The delamination results indicated that there were no significant differences between those obtained for the combinations of wood treated with CCA and wood in natura. The results of the shear tests on the glue lines revealed significant differences when comparing the performance of wood treated with CCA to that of untreated (in natura) wood. Specifically, when using Cascophen 216-M and polyurethane AG 101 adhesives, the treated wood demonstrated notably different shear strengths. This indicates that the preservative treatment with chromated copper arsenate alters the bonding effectiveness of these adhesives, highlighting the importance of selecting appropriate adhesive formulations for treated wood to ensure optimal bonding quality. The only species/adhesive combination that showed a delamination limit lower than 4 % was the one that considered natural wood glued with Cascophen 216-M adhesive. To confirm these results is essential a complementary study evaluating the viscosity of the resins used.

Downloads

References

ABNT 1997. Projeto de estruturas de madeira. ABNT NBR 7190. ABNT: Rio de Janeiro – RJ.

ABNT. 2022. Métodos de ensaio para corpos de prova isentos de defeitos para madeiras de florestas nati- vas ABNT NBR 7190-3. ABNT: Rio de Janeiro - RJ.

ABNT. 2009. Eucalypt treated round wood for rural constructions - Requirements. ABNT NBR 9480. ABNT: Rio de Janeiro – RJ.

Alade, A.A.; Naghizadeh, Z.; Wessels, C.B.; Tyhoda, L. 2021. A review of the effects of wood preservative impregnation on adhesive bonding and joint performance. Journal of Adhesion Science and Technology 36(15): 1593-1617. https://doi.org/10.1080/01694243.2021.1981651

Almeida, A.S.; Crisculo, G.; Almeida, T.H.; Christoforo, A.L.; Chahud, E.; Branco, L.A. M.N.; Pinheiro, R.V.; Lahr, F.A.R. 2019. Influence of CCA-A preservative on physical-mechanical properties of Brazilian tropical woods. BioResources 14(2): 3031-3041. https://doi.org/10.15376/biores.14.2.3031-3041

Andrade, C. R.; Dias-Júnior, A. F.; Brito, J. O.; Lana, A. Q.; Guimarães-Junior, J. B.; Faria, D. L. 2020. Evaluation of contamination of wooden residue sources by human activities. Scientia Forestalis 48(128). e3161. https://doi.org/10.18671/scifor.v48n128.05

ASTM. 2019. Standard Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber ASTM. ASTM D245-19. ASTM: West Conshohocken, PA, EUA.

Azambuja, M.A.; Dias, A.A. 2006. Use of Castor Oil-based Polyurethane Adhesive in the Production of Glued Laminated Timber Beams. Materials Research 9(3): 1- 5. https://doi.org/10.1590/S1516-14392006000300008

Bockel, S.; Mayer, I.; Konnerth, J.; Harling, S.; Niemz, P.; Swaboda, C.; Beyer, M.; Bieri, N.; Weiland, G.; Pichelin, F. 2019. The role of wood extractives in structural hardwood bonding and their influence on different adhesive systems. International Journal of Adhesion and Adhesives 91: 43-53. https://doi.org/10.1016/j.ijadhadh.2019.03.001

Brito, F.M.S.; Paes, J.B.; Oliveira, J.T. da S.; Arantes, M.D.C.; Vidaurre, G.B.; Brocco, V.F. 2018. Physico-mechanical characterization of heat-treated glued laminated bamboo. Construction and Building Materials 190: 719-727. https://doi.org/10.1016/j.conbuildmat.2018.09.057

CEN. 2013. Timber structures: Glued laminated timber and glued solid timber - requirements. EN 14080. EN: Brussels - Belgium.

Dias, A.M.; Martins, C.E.J.; Dias, A.M.P.G. 2020. Influence of the Treatment Phase on the Gluing Performance of Glued Laminated Timber. BioResources 15(3): 5725-5736. https://doi.org/10.15376/biores.15.3.5725-5736

Freitas, R.R.; Molina, J.C.; Calil-Júnior, C. 2010. Mathematical model for timber decay in contact with the ground adjusted for the state of São Paulo, Brazil. Materials Research 13(2): 151-158. https://doi.org/10.1590/S1516-14392010000200006

Lima, P.A.F.; Gouveia, F.N.; Baraúna, E.E.P.; Sette Junior, C.R. 2020. CCB retention and penetration in Eucalyptus fence posts in function of condition of preservative treatment, Floresta 50(2). e1345. https://doi.org/10.5380/rf.v50i2.63737

Molina, J.C.; Calil-Júnior, C.; Freitas, R.R. 2011. Mathematical model to estimate of the deterioration of wooden poles in contact with soil used in rural areas. Engenharia Agrícola 31(5): 1015-1026. https://doi.org/10.1590/S0100-69162011000500019

Motta, J.P.; Oliveira, J.T.D.S.; Paes, J.B.; Alves, R.C.; Vidaurre, G.B. 2014. Evaluation of the shear strength of bonded joints of teak wood (Tectona grandis). Scientia Forestalis 42(104): 615-621. https://doi.org/10.13140/RG.2.1.3697.6169

Musah, M.; Wang, X.; Dickinson, Y.; Ross, R.J.; Rudnicki, M.; Xie, X. 2021. Durability of the adhesive bond in cross-laminated northern hardwoods and softwoods. Construction and Building Materials 307. e124267. https://doi.org/10.1016/j.conbuildmat.2021.124267

Oliveira, C.A.B.; Silva, J.V.F.; Bianchi, N.A.; Campos, C.I.; Oliveira, K.A.; Galdino, D. S.; Bertolini, M.S.; Morais, C.A.G.; De-Souza, A.J.D.; Molina, J.C. 2020. Influence of Indian cedar particle pre-treatments on cement-wood composite properties. BioResources 15(1): 1656-1664. https://doi.org/10.15376/biores.15.1.1656-1664

Petrauski, S.M.F.C.; Silva, J. de C.; Petrauski, A.; Lucia, R.M.D. 2016. Analysis of Eucalyptus glued-laminated timber porticos structural performance. Revista Árvore 40(5): 931-939. https://doi.org/10.1590/0100-67622016000500017

Poleto, S.F.S.; Aquino, V.B. de M.; Chahud, E.; Pinheiro, R.V.; Branco, L.A.M.N.; Silva, D.A.L.; De-Campos, C.I.; Molina, J.C.; De-Carvalho, C.M.; Christoforo, A.L.; Lahr, F. A.R. 2020. Evaluation of CCB-preserved medium density particleboards under natural weathering. BioResources 15(2):3678-3687. https://doi.org/10.15376/biores.15.2.3678-3687

Samani, A.; Ganguly, S.; Kanyal, R.; Tripathi, S. 2019. Effect of microwave pre-treatment on preservative retention and treatability of Melia composita wood. Journal of Forest Science 65(10): 391-396. https://doi.org/10.17221/39/2019-JFS

Stringari, E.H.; Petrauski, A.; Petrauski, S.M. C.; Azevedo, R.L.; Savaris, G. 2020. Construction and testing of glued laminated timber frames for use in laying poultry houses. Engenharia Agrícola 40(2):122-131. https://doi.org/10.1590/1809-4430-eng.agric.v40n2p122-131/2020

Sun, X.; He, M.; Li, Z. 2020. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Construction and Building Materials 249. e118751. https://doi.org/10.1016/j.conbuildmat.2020.118751

Thorhallsson, E.R.; Hinriksson, G.I.; Snæbjörnsson, J.T. 2017. Strength and stiffness of glulam beams reinforced with glass and basalt fibres. Composites Part B: Engineering 115: 300-307. https://doi.org/10.1016/j.compositesb.2016.09.074

Treu, A.; Bredesen, R.; Bongers, F. 2020. Enhanced bonding of acetylated wood with an MUF-based adhesive and a resorcinol formaldehyde-based primer. Holzforschung 74(4): 382-390. https://doi.org/10.1515/hf-2019-0056

Zhan, Z.; Wang, C.; Yap, J.B.H.; Loi, M.S. 2020. Retrofitting ancient timber glulam mortise & tenon construction joints through computer-aided laser cutting. Heliyon 6(4). e03671. https://doi.org/10.1016/j.he-liyon.2020.e03671

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.