Estudio comparativo de productos de madera laminada unidos con distintos tipos de clavijas

DOI:

https://doi.org/10.22320/s0718221x/2025.22Keywords:

Clavijas de madera, conexiones de madera, ensayos de flexión, madera laminada, madera masiva, Pinus taeda, sistemas constructivos sosteniblesAbstract

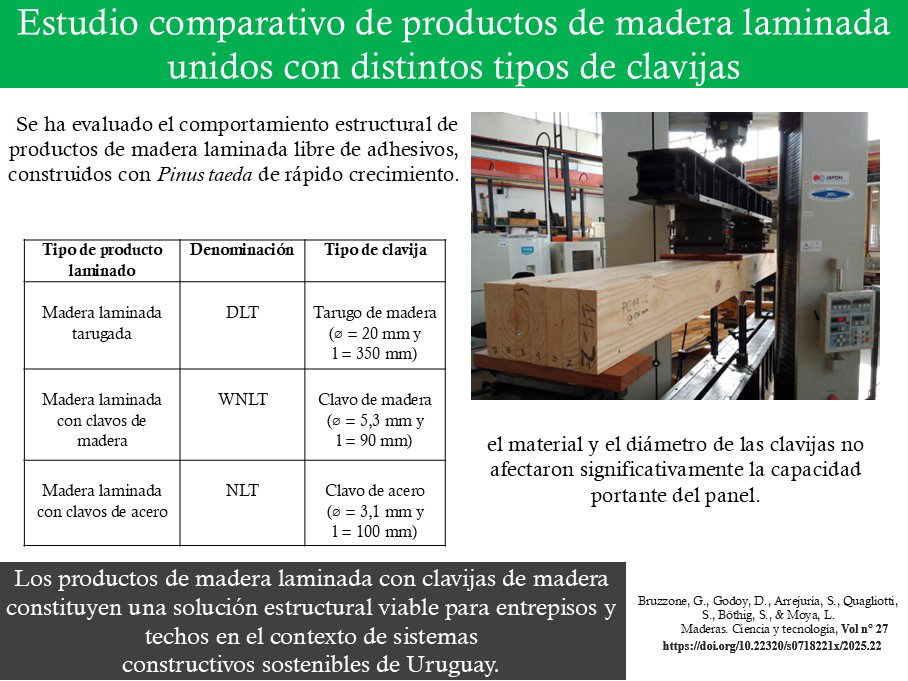

La búsqueda de soluciones constructivas sostenibles ha impulsado el uso de productos de madera masiva como alternativa a componentes estructurales de hormigón armado y acero. En este contexto, el presente trabajo informa sobre el comportamiento estructural de productos de madera laminada construidos sin adhesivos y con madera de pino uruguayo (Pinus taeda) de rápido crecimiento. Para la fabricación, se utilizaron lamelas C14, unidas mediante tarugos de madera de 20 mm de diámetro, clavos de madera y clavos de acero colocados neumáticamente, de 5,3 y 3,2 mm de diámetro, respectivamente. Se evaluaron dos patrones de clavado, en línea recta horizontal y zigzag, y tres espaciamientos entre clavijas, 300 mm, 250 mm y 150 mm. Se realizaron ensayos de corte perpendicular a las fibras en conexiones de madera y ensayos de flexión en cuatro puntos en paneles de tamaño estructural, y se obtuvieron el módulo de deslizamiento y las propiedades de flexión, respectivamente. Las conexiones con clavos de madera presentaron valores de módulo de deslizamiento significativamente superiores (2,54 kN/mm) a las conexiones con tarugos de madera (1,47 kN/mm) y con clavos de acero (1,25 kN/mm). Los resultados de flexión indicaron que la resistencia (16,8–31,6 MPa) y la rigidez (6213–8103 MPa) de los paneles con tarugos de madera, clavos de madera y clavos de acero no mostraron diferencias significativas y son similares a los valores de las piezas individuales que los conforman. Los hallazgos encontrados sugieren que la madera laminada fabricada con pino de rápido crecimiento unida mediante clavijas de madera en configuraciones superficiales aparece como una solución estructural viable para entrepisos y techos en el contexto de sistemas constructivos sostenibles.

Downloads

References

Abergel, T.; Dean, B.; Dulac, J. 2017. Global Status Report 2017: Towards a zero-emission, efficient, and resilient buildings and construction sector. United Nations Environment Programme. Nairobi, Kenya. https://globalabc.org/resources/publications/2017-global-status-report-buildings-and-construction

Ahmed, S.; Arocho, I. 2020. Mass timber building material in the U.S. construction industry: determining the existing awareness level, construction-related challenges, and recommendations to increase its current acceptance level. Cleaner Engineering and Technology 1: e100007. https://doi.org/10.1016/j.clet.2020.100007

Bell, T.A. 2018. A detailed investigation into the engineering properties and challenges affecting the potential introduction of a UK grown dowel-laminated timber floor panel into the domestic construction market. Thesis Doctor of Architecture, University of Strathclyde, Faculty of Engineering. Glasgow, United Kingdom. https://doi.org/10.48730/yt00-d987

Bruzzone, G. 2023. Evaluación experimental de placas de madera laminada tarugada para la construcción de entrepisos y techos de viviendas en Uruguay. Tesis de Maestría, Universidad de la República, Facultad de Agronomía. Montevideo, Uruguay. https://hdl.handle.net/20.500.12008/36902

Bruzzone, G.; Godoy, D.; Quagliotti, S.; Arrejuría, S.; Böthig, S.; Moya, L. 2023. Experimental investigation on dowel laminated timber made of Uruguayan fast-grown species. Forests 14(11): e2215. https://doi.org/10.3390/f14112215

Casaravilla, J. 2021. Propiedades de flexión de paneles de madera laminada clavada de pino para uso en viviendas construidas por el sistema cooperativo de ayuda mutua en Uruguay. Tesis Magister en Construcción en Madera, Universidad del Bío-Bío, Facultad de Arquitectura, Construcción y Diseño. Concepción, Chile. http://repobib.ubiobio.cl/jspui/handle/123456789/4304

Ceraldi, C.; Lippiello, M.; D’ambra, C.; Prota, A. 2018. The Influence of Dowel-Bearing Strength in Designing Timber Pegged Timber Joints. International Journal of Architectural Heritage 12(3): 362-375. https://doi.org/10.1080/15583058.2017.1323249

CWC. 2024. Nail-Laminated Timber: Canadian Design and Construction Guide. Canadian Wood Council. Ottawa, Canada. https://www.naturallywood.com/wp-content/uploads/NLT-Guide-Version2-2024-1.pdf

Derikvand, M.; Jiao, H.; Kotlarewski, N.; Lee, M.; Chan, A.; Nolan, G. 2019. Bending performance of nail-laminated timber constructed of fast-grown plantation eucalypt. European Journal of Wood and Wood Products 77: 421-437. https://doi.org/10.1007/s00107-019-01408-9

Derikvand, M.; Serveh, H.; Fink, G. 2021. Mechanical properties of dowel laminated timber beams with connectors made of salvaged wooden materials. Journal of Architectural Engineering 27(4): e04021035. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000513

EN. 1991. Timber structures. Joints made with mechanical fasteners. General principles for the determination of strength and deformation characteristics. EN 26891. CEN: Brussels, Belgium.

EN. 2002. Moisture Content of a Piece of Sawn Timber-Part 1: Determination by Oven Dry Method. EN 13183-1. CEN: Brussels, Belgium.

EN. 2012. Timber Structures. Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties. EN 408:2011+A1:2012. CEN: Brussels, Belgium.

EN. 2016. Structural timber - Strength classes. EN 338. CEN: Brussels, Belgium.

EN. 2016. Eurocode 5. Design of Timber Structures-Part 1-1: General-Common Rules and Rules for Buildings. EN 1995-1-1. CEN: Brussels, Belgium.

El-Houjeyri, I.; Thi, V.D.; Oudjene, M.; Khelifa, M.; Rogaume, Y.; Sotayo, A.; Guan, Z. 2019. Experimental investigations on adhesive free laminated oak timber beams and timber-to-timber joints assembled using thermo-mechanically compressed wood dowels. Construction and Building Materials 222: 288-299. https://doi.org/10.1016/j.conbuildmat.2019.05.163

Feng, W.; He, M.; Ou, J.; Li, Z. 2025. Bending performance of nail laminated timber (NLT): Experi- ments and probabilistic modelling based on Monte Carlo simulation. Engineering Structures 323 (B): e119317. https://doi.org/10.1016/j.engstruct.2024.119317

Giordano, L.; Derikvand, M.; Fink, G. 2023. Bending properties and vibration characteristics of dowel-laminated timber panels made with short salvaged timber elements. Buildings 13(1): e199. https://doi.org/10.3390/buildings13010199

Haller, P.; Pannke, K. 1998. Structural and physical behaviour of nailed laminated timber elements. In: Proceedings of World Conference of Timber Engineering (WCTE 1998). August 17-20, 1998. Switzerland, 2: 230-237.

Han, L.; Kutnar, A.; Sandak, J.; Sustersic, I.; Sandberg, D. 2023. Adhesive-and metal-free assembly techniques for prefabricated multi-layered wood products: a review on wooden connectors. Forests 14(2): e311. https://doi.org/10.3390/f14020311

ICC. 2024. International Building Code. International Code Council. Washington, D.C., United States. https://codes.iccsafe.org/content/IBC2024P1

Li, Z.; Feng, W.; He, M.; Chen, F.; Sun, X. 2023. Bending performance of nail laminated timber: Experimental, analytical and numerical analyses. Construction and Building Materials 389: e131766. https://doi.org/10.1016/j.conbuildmat.2023.131766

Moya, L.; Cardoso, A.; Cagno, M.; O´Neill, H. 2015. Caracterización estructural de madera aserrada de pinos cultivados en Uruguay. Maderas. Ciencia y Tecnología 17(3): 597-612. http://dx.doi.org/10.4067/S0718-221X2015005000053

Ogunrinde, O. 2019. Evaluation of bending performance of nail laminated and dowel laminated timber. Thesis Master of Science in Forest Engineering, University of New Brunswick, Faculty of Forestry and Envi- ronmental Management. New Brunswick, Canada. https://unbscholar.lib.unb.ca/handle/1882/14045

Pereira, M.; Minari, V.; Sohier, L.; Descamps, T.; Calil, C. 2019. Comparativo da rigidez e ruptura de dois painéis estruturais de madeira macica lamelar unida por cavilhas. En Actas del 4° Congreso Latinoamericano de estructuras de maderas (CLEM 2019). 18-20 de setiembre, 2019. Uruguay, 9 p. https://www.fing.edu.uy/sites/default/files/202103/Proceedings_CLEM2019_ISBN_parte_1.pdf

Plowas W.; Bell, T.; Hairstans, R.; Williamson, J. 2016. Understanding the compatibility of UK resource for dowel laminated timber construction. TH Building Construction, 12 p. http://researchrepository.napier.ac.uk/id/eprint/10195

Riggio, M.; Pauliny, D.; Sandak, J.; Sandak, A. 2013. Novel Nail-like Wood Connectors. Advanced Materials Research 778: 647-654. https://doi.org/10.4028/www.scientific.net/AMR.778.647

Riggio, M.; Sandak, J.; Sandak, A. 2016. Densified Wooden Nails for New Timber Assemblies and Restoration Works: A Pilot Research. Construction and Building Materials 102(2): 1084-1092. https://doi.org/10.1016/j.conbuildmat.2015.06.045

Ruan, G.; Filz, G.H.; Fink, G. 2021. An integrated architectural and structural design concept by using local, salvaged timber. In: Proceedings of the Annual Symposium of the International Association for Shell and Spatial Structures (IASS) and the 7th International Conference on Spatial Structures: Inspiring the Next Generation. 23-27 September, 2021. United Kingdom, 12 p. https://urn.fi/URN:NBN:fi:aalto-2021112410391

Ruan, G.; Filz, G.H.; Fink, G. 2022. Shear capacity of timber-to-timber connections using wooden nails. Wood Material Science & Engineering 17(1): 20-29. https://doi.org/10.1080/17480272.2021.1964595

Sandberg, L.; Bulleit, W. M.; Reid, E. 2000. Strength and stiffness of oak pegs in traditional timber-frame joints. J Struct Eng 126(6): 717-723. https://doi.org/10.1061/(ASCE)0733-9445(2000)126:6(717)

Sandhaas, C.; Schädle, P.; Ceccotti, A. 2018. Innovative timber building systems: Comparative testing and modelling of earthquake behaviour. Bulletin of Earthquake Engineering 16: 1961-1985. https://doi.org/10.1007/s10518-017-0264-x

Schmidt, R. J.; Daniels, C. E. 1999. Design considerations for mortise and tenon connections. Report for Timber Framers Guild. Massachusetts, United States.

Sosa-Zitto, M.; Köhler, J.; Piter, J. 2013. Load-carrying capacity of timber-to-timber joints of fast-grow- ing Argentinean Eucalyptus grandis with nails of small diameter laterally loaded in double shear: Analysis according to the criterion adopted by European standards. European Journal of Wood and Wood Products 72(1): 21-31. https://doi.org/10.1007/s00107-013-0748-6

Sotayo, A.; Bradley, D.; Bather, M.; Sareh, P.; Oudjene, M.; El-Houjeyri, I.; Harte, A.M.; Mehra, S.; O’Ceallaigh, C.; Haller, P.; Namari, S.; Makradi, A.; Belouettar, S.; Bouhala, L; Deneufbourg, F.; Guan, Z. 2020. Review of state of the art of dowel laminated timber members and densified wood materials as sustainable engineered wood products for construction and building applications. Developments in the Built Environment 1: e100004. https://doi.org/10.1016/j.dibe.2019.100004

Tannert, T. 2002. Estudio de elementos laminados clavados para la construcción de viviendas de madera en Chile. Tesis Magister en Ciencia y Tecnología de la Madera, Universidad del Bío-Bío. Concepción, Chile. http://dx.doi.org/10.4067/S0718-221X2002000200013

UNIT. 2018. Madera aserrada de uso estructural - Clasificación visual - Madera de pino taeda y pino ellioti (Pinus taeda y Pinus elliottii). UNIT 1261. UNIT: Montevideo, Uruguay.

Ugarte, J.; Sierra, A.; Codriansky, K. 2022. Hoja de ruta para la construcción de vivienda social en madera en Uruguay. Ministerio de Vivienda y Ordenamiento Territorial: Montevideo, Uruguay. https://www.gub.uy/ministerio-vivienda-ordenamiento-territorial/comunicacion/publicaciones/hoja-ruta-construccion-vi-vienda-social-madera-uruguay

Uruguay XXI. 2023. Sector forestal en Uruguay. Promoción de inversiones, exportaciones e imagen país. Montevideo, Uruguay. https://www.uruguayxxi.gub.uy/es/centro-informacion/articulo/sector-forestal-en-uru-guay/

Yeh, Y.H.; Yeh, Y.C. 2024. Bending behaviour and failure modes of non-glue-laminated timber beams composed of wooden dowels and self-tapping screws. Buildings 14(2): e394. https://doi.org/10.3390/build-ings14020394

Zhu, W.; Gong, M.; Chui, Y.H., Li, L. 2021. Improved fastening designs for bridge decks made of mechanically-laminated timber. Construction and Building Materials 266 (B): e121166. https://doi.org/10.1016/j.conbuildmat.2020.121166

Zhu, X.; Xue, Y.; Qi, P.; Lan, Q.; Qian, L.; Shen, J.; Gao, Y.; Li, J.; Mei, C.; Li, S. 2023. Flexural properties of wooden nail friction welding of laminated timber. BioResources 18(1): 1166-1176. https://doi.org/10.15376/biores.18.1.1166-1176

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.