Clasificación de defectos en tableros melamínicos mediante imágenes multiespectrales y redes neuronales convolucionales

DOI:

https://doi.org/10.22320/s0718221x/2025.39Keywords:

Clasificación de defectos, clasificación multiclase, imágenes multiespectrales, tableros melamínicos, redes neuronales convolucionales, visión por computadorAbstract

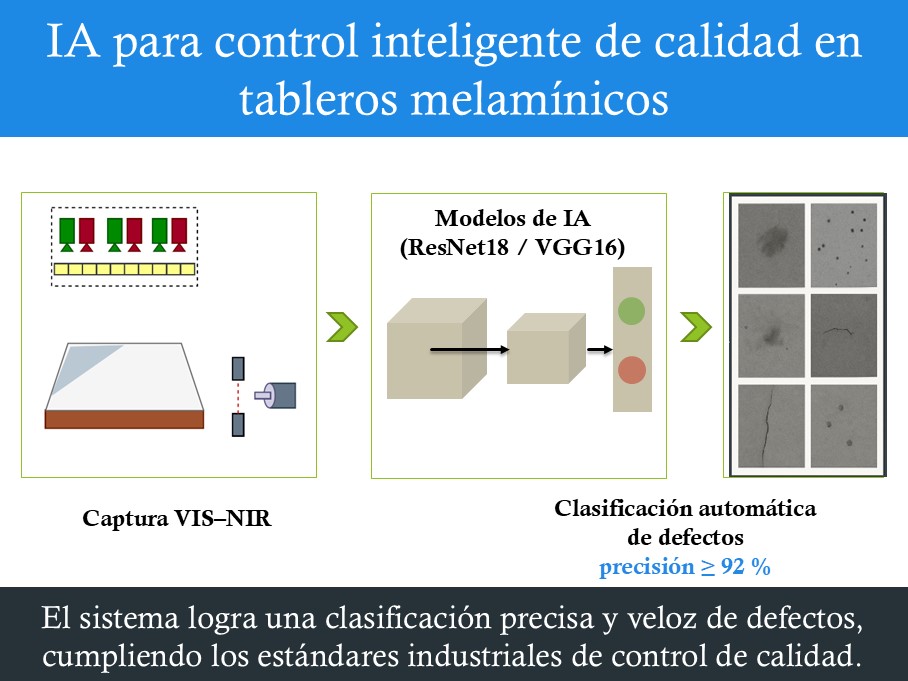

La industria manufacturera de la madera requiere cada vez más sistemas automáticos e inteligentes para la detección de defectos, dado que el control de calidad basado en inspección visual por operadores humanos presenta variabilidad y limitaciones en su desempeño. Este trabajo aborda dicha necesidad mediante la evaluación de redes neuronales convolucionales para la clasificación automática de defectos en tableros revestidos con melamina. Para ello, se capturaron imágenes multiespectrales en las bandas visible (VIS) e infrarroja cercana (NIR), utilizando un sistema de cámaras instalado en una línea de producción industrial. Se evaluaron los modelos Residual Network 18 y Visual Geometry Group 16, obteniendo niveles de precisión comparables a los alcanzados por operadores expertos. Los resultados superaron el 92 % de precisión en todas las tareas de clasificación, lo que sugiere la aplicabilidad práctica del enfoque propuesto en sistemas automatizados de control de calidad.

Downloads

References

Aguilera, C.A.; Aguilera, C.; Sappa, A.D. 2018. Melamine faced panels defect classification beyond the visible spectrum. Sensors 18(11). e3644. https://doi.org/10.3390/s18113644 DOI: https://doi.org/10.3390/s18113644

Ali, H.S.; Ismail, A.I.; El-Rabaie, E.S.M.; Abd El-Samie, F.E. 2023. Deep residual architectures and ensemble learning for efficient brain tumour classification. Expert Systems 40(6). e13226. https://doi.org/10.1111/exsy.13226 DOI: https://doi.org/10.1111/exsy.13226

Arnia, F.; Munadi, K. 2015. Real time textile defect detection using GLCM in DCT-based compressed images. In: Proceedings of the 6th International Conference on Modeling, Simulation, and Applied Optimization (ICMSAO). IEEE: Istanbul, Turkey. pp. 1-6. https://doi.org/10.1109/ICMSAO.2015.7152203 DOI: https://doi.org/10.1109/ICMSAO.2015.7152203

Bigdeli, S.; Süsstrunk, S. 2019. Deep semantic segmentation using NIR as extra physical information. In: Proceedings of the IEEE International Conference on Image Processing (ICIP). IEEE: Taipei, Taiwan. pp. 2439-2443. https://doi.org/10.1109/ICIP.2019.8803242 DOI: https://doi.org/10.1109/ICIP.2019.8803242

de Sá, F.P.; Aguilera, C.; Aguilera, C.A.; Conci, A. 2022. ICT Applications for Smart Cities. In: ICT Applications for Smart Cities. Springer: Cham, Switzerland. https://doi.org/10.1007/978-3-031-06307-7_9 DOI: https://doi.org/10.1007/978-3-031-06307-7_9

Gao, Y.; Gao, L.; Li, X.; Yan, X. 2020. A semi-supervised convolutional neural network-based method for steel surface defect recognition. Robotics and Computer-Integrated Manufacturing 61. e101825. https://doi.org/10.1016/j.rcim.2019.101825 DOI: https://doi.org/10.1016/j.rcim.2019.101825

Grand View Research. 2024. Wood Based Panel Market (2025-2030): Size, Share & Trends Analysis Report By Product (Plywood, MDF, HDF, Particleboard, OSB, Softboard, Hardboard), By Application (Furniture, Construction, Packaging), By Region, And Segment Forecasts. Grand View Research: San Francisco,USA

Hamdi, A.A.; Fouad, M.M.; Sayed, M.S.; Hadhoud, M.M. 2017. Patterned fabric defect detection system using near infrared imaging. In: Proceedings of the 8th International Conference on Intelligent Computing and Information Systems (ICICIS). IEEE: Cairo, Egypt. pp. 111-117. https://doi.org/10.1109/INTELCIS.2017.8260041 DOI: https://doi.org/10.1109/INTELCIS.2017.8260041

He, K.; Zhang, X.; Ren, S.; Sun, J. 2016. Deep residual learning for image recognition. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR). IEEE: Las Vegas, NV, USA. pp. 770-778. https://doi.org/10.1109/cvpr.2016.90 DOI: https://doi.org/10.1109/CVPR.2016.90

He, T.; Liu, Y.; Xu, C.; Zhou, X.; Hu, Z.; Fan, J. 2019. A fully convolutional neural network for wood defect location and identification. IEEE Access 7: 123453-123462. https://doi.org/10.1109/ACCESS.2019.2937461 DOI: https://doi.org/10.1109/ACCESS.2019.2937461

Hu, J.; Song, W.; Zhang, W.; Zhao, Y.; Yilmaz, A. 2019. Deep learning for use in lumber classification tasks. Wood Science and Technology 53: 505-517. https://doi.org/10.1007/s00226-019-01086-z DOI: https://doi.org/10.1007/s00226-019-01086-z

Ismail, L.; Waseem, M.D. 2023. Towards a deep learning pain-level detection deployment at UAE for patient-centric-pain management and diagnosis support: framework and performance evaluation. Procedia Computer Science 220: 339-347. https://doi.org/10.1016/j.procs.2023.03.044 DOI: https://doi.org/10.1016/j.procs.2023.03.044

Kamal, K.; Qayyum, R.; Mathavan, S.; Zafar, T. 2017. Wood defects classification using Laws texture energy measures and supervised learning approach. Advanced Engineering Informatics 34: 125-135. https://doi.org/10.1016/j.aei.2017.09.007 DOI: https://doi.org/10.1016/j.aei.2017.09.007

Kim, G.B. 2013. Micro defect detection in solar cell wafer based on hybrid illumination and near-infrared optics. In: Proceedings of the 9th Asian Control Conference (ASCC). IEEE: Istanbul, Turkey. pp. 1-5. https://doi.org/10.1109/ASCC.2013.6606013 DOI: https://doi.org/10.1109/ASCC.2013.6606013

Lee, J.; Park, Y.; Jeon, B. 2018. Low intensity RGB texture enhancement based on near infrared image using perceptual information. In: Proceedings of the 10th International Conference on Communications, Circuits and Systems (ICCCAS). IEEE: Chengdu, China. pp. 422-425. https://doi.org/10.1109/ICCCAS.2018.8769208 DOI: https://doi.org/10.1109/ICCCAS.2018.8769208

Liu, C.; Chen, K.; Wang, N.; Shi, W.; Jia, N. 2025. A lightweight multi-scale feature fusion method for detecting defects in water-based wood paint surfaces. Measurement 235. e117505. https://doi.org/10.1016/j.measurement.2025.117505 DOI: https://doi.org/10.1016/j.measurement.2025.117505

Liu, Z.; Wu, J.; Fu, L.; Majeed, Y.; Feng, Y.; Li, R.; Cui, Y. 2019. Improved kiwifruit detection using pretrained VGG16 with RGB and NIR information fusion. IEEE Access 8: 2327-2336. https://doi.org/10.1109/ACCESS.2019.2962513 DOI: https://doi.org/10.1109/ACCESS.2019.2962513

Parés, F.; Arias-Duart, A.; Garcia-Gasulla, D.; Campo-Francés, G.; Viladrich, N.; Ayguadé, E.; Labarta, J. 2022. The MAMe dataset: on the relevance of high resolution and variable shape image properties. Applied Intelligence 52(10): 11703-11724. https://doi.org/10.1007/s10489-021-02951-w DOI: https://doi.org/10.1007/s10489-021-02951-w

Research and Markets. 2020. Wood Based Panel Market Size, Share & Trends Analysis Report by Product. Research and Markets: Dublin, Ireland

Rudakov, N.; Eerola, T.; Lensu, L.; Kälviäinen, H.; Haario, H. 2019. Detection of mechanical damages in sawn timber using convolutional neural networks. In: Proceedings of the 40th German Conference on Pattern Recognition (GCPR). Springer: Stuttgart, Germany. pp. 115-126. https://doi.org/10.1007/978-3-030-12939-2_9 DOI: https://doi.org/10.1007/978-3-030-12939-2_9

Salamati, N.; Larlus, D.; Csurka, G.; Süsstrunk, S. 2012. Semantic image segmentation using visible and near-infrared channels. In: Proceedings of the European Conference on Computer Vision (ECCV). Springer: Florence, Italy. pp. 461-471. https://doi.org/10.1007/978-3-642-33868-7_46 DOI: https://doi.org/10.1007/978-3-642-33868-7_46

Sharma, V.; Hardeberg, J.Y.; George, S. 2017. RGB-NIR image enhancement by fusing bilateral and weighted least squares filters. In: Proceedings of the Color and Imaging Conference (CIC). Society for Imaging Science and Technology: Lillehammer, Norway. pp. 330-338. https://doi.org/10.2352/J.ImagingSci.Technol.2017.61.4.040409 DOI: https://doi.org/10.2352/J.ImagingSci.Technol.2017.61.4.040409

Simonyan, K.; Zisserman, A. 2015. Very deep convolutional networks for large-scale image recognition. In: Proceedings of the 3rd International Conference on Learning Representations (ICLR). ICLR: San Diego, CA, USA. https://doi.org/10.48550/arXiv.1409.1556

Sun, Y.; Lin, Q.; He, X.; Zhao, Y.; Dai, F.; Qiu, J.; Cao, Y. 2021. Wood species recognition with small data: A deep learning approach. International Journal of Computational Intelligence Systems 14(1): 1451-1460. https://doi.org/10.2991/ijcis.d.210423.001 DOI: https://doi.org/10.2991/ijcis.d.210423.001

Urbonas, A.; Raudonis, V.; Maskeliūnas, R.; Damaševičius, R. 2019. Automated identification of wood veneer surface defects using faster region-based convolutional neural network with data augmentation and transfer learning. Applied Sciences 9(22). e4898. https://doi.org/10.3390/app9224898 DOI: https://doi.org/10.3390/app9224898

Wan, Z.; Shao, X. 2023. Disease classification model based on multi-modal feature fusion. IEEE Access 11: 27536-27545. https://doi.org/10.1109/ACCESS.2023.3252011 DOI: https://doi.org/10.1109/ACCESS.2023.3252011

Wang, J.; Li, Q.; Gan, J.; Yu, H. 2017. Fabric defect detection based on improved low-rank and sparse matrix decomposition. In: Proceedings of the IEEE International Conference on Image Processing (ICIP). IEEE: Beijing, China. pp. 2776-2780. https://doi.org/10.1109/ICIP.2017.8296788 DOI: https://doi.org/10.1109/ICIP.2017.8296788

Wu, Y.; Liu, J.; Zhang, Y.; Yu, L.; Wu, J. 2019. Detection algorithm of aluminum surface defects using machine vision. In: Proceedings of the International Conference on Image, Video and Signal Processing (IVSP). ACM: Shanghai, China. pp. 16-22. https://doi.org/10.1145/3317640.3317661 DOI: https://doi.org/10.1145/3317640.3317661

Yong-Hua, X.; Jin-Cong, W. 2015. Study on the identification of the wood surface defects based on texture features. Optik 126(19): 2231-2235. https://doi.org/10.1016/j.ijleo.2015.05.101 DOI: https://doi.org/10.1016/j.ijleo.2015.05.101

Yu, H.; Liang, Y.; Liang, H.; Zhang, Y. 2019. Recognition of wood surface defects with near infrared spectroscopy and machine vision. Journal of Forestry Research 30(6): 2379-2386. https://doi.org/10.1007/s11676-018-00874-w DOI: https://doi.org/10.1007/s11676-018-00874-w

Yuce, B.; Mastrocinque, E.; Packianather, M.S.; Pham, D.; Lambiase, A.; Fruggiero, F. 2014. Neural network design and feature selection using principal component analysis and Taguchi method for identifying wood veneer defects. Production and Manufacturing Research 2(1): 291-308. https://doi.org/10.1080/21693277.2014.892442 DOI: https://doi.org/10.1080/21693277.2014.892442

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.