Physical and mechanical assessment of Itauba wood welded by rotary friction

DOI:

https://doi.org/10.22320/s0718221x/2025.37Palabras clave:

Rotary friction welding, Mezilaurus itauba, dowel joints, shear strength, tensile shear strength testing, tropical hardwoodResumen

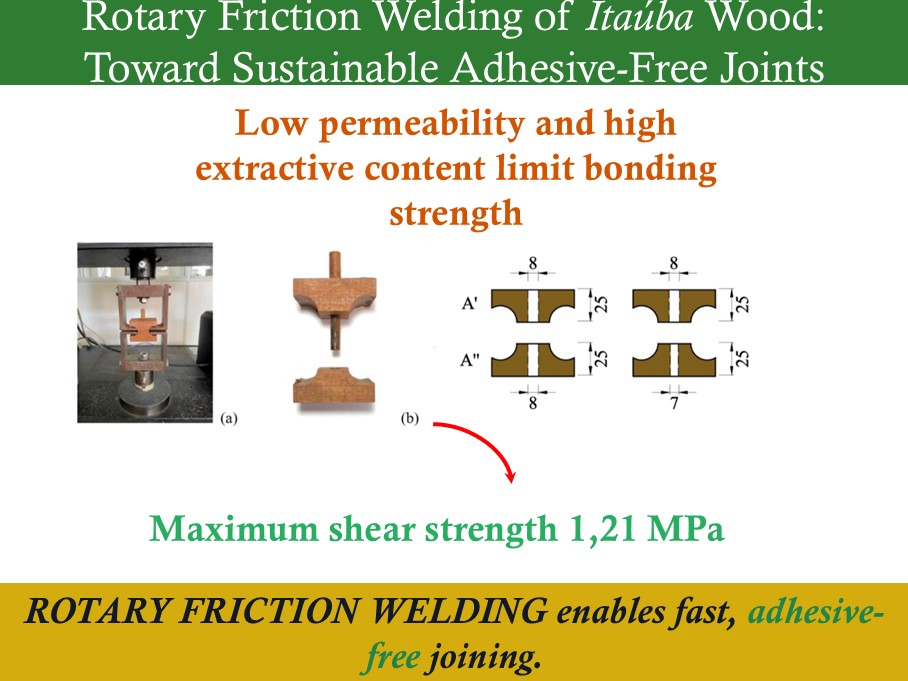

Rotary friction welding is a rapid and sustainable wood joining method, which eliminates the need for conventional adhesives or mechanical fasteners. Its application to Brazilian tropical hardwoods like itauba remains largely unexplored. The absence of established welding parameters for itauba-itauba (dowel-substrate) joints leads to unpredictable mechanical performance, limiting the industrial viability of this technique. This exploratory research aimed to evaluate the physical characteristics of the welded interface using scanning electron microscopy and assessed the influence of pre-drilled hole stage (one- and two-stage) and feed rate (300 mm/min, 400 mm/min, and 500 mm/min) on the mechanical performance of itauba welded joints. The ultimate objective was to determine the optimal welding parameters. The results demonstrate that the dowel wood fibers were covered by softened intercellular material, forming a smooth and uniform surface. The average taper rate of the dowels, from 3,72 % to 5,39 %, was influenced by the pre-drilled hole stage. The highest taper rates were obtained for two-stage pre-drilled holes, in which piece A had a smaller diameter (7 mm). Tensile testing demonstrated that specimens with a one-stage pre-drilled hole exhibited higher maximum pull-out loads than those with two-stages. The highest average shear strength, 1,21 MPa, was obtained for 1-stage pre-drilled hole and 300 mm/min or 400 mm/min of feed rate.

Descargas

Citas

Associação Brasileira de Normas Técnicas. ABNT. 2022. Projeto de estruturas de madeira – Parte 3: Métodos de ensaio para corpos de provas isentos de defeitos para madeiras de florestas nativas. ABNT NBR 7190. ABNT: Rio de Janeiro, Brasil.

Auchet, S.; Segovia, C.; Mansouri, H.R.; Meausoone, P.J.; Pizzi, A.; Omrani, P. 2010. Accelerating vs constant rate of insertion in wood dowel welding. Journal of Adhesion Science and Technology 24(7): 1319-1328. https://doi.org/10.1163/016942409X12598231568384 DOI: https://doi.org/10.1163/016942409X12598231568384

Belleville, B.; Stevanovic, T.; Pizzi, A.; Cloutier, A.; Blanchet, P. 2013. Determination of optimal wood-dowel welding parameters for two North American hardwood species. Journal of Adhesion Science and Technology 27(5-6): 566-576. https://doi.org/10.1080/01694243.2012.687596 DOI: https://doi.org/10.1080/01694243.2012.687596

Belleville, B.; Ozarska, B.; Pizzi, A. 2016. Assessing the potential of wood welding for Australian eucalypts and tropical species. European Journal of Wood and Wood Products 74: 753-757. https://doi.org/10.1007/s00107-016-1067-5 DOI: https://doi.org/10.1007/s00107-016-1067-5

Biwôlé, J.J.E.; Biwôlé, A.B.; Mfomo, J.Z.; Segovia, C.; Pizzi, A.; Chen, X.; Fongnzossie, E.F.; Ateba, A.; Meausoone, P.J. 2022. Causes of differential behavior of extractives on the natural cold water durability of the welded joints of three tropical woods. Journal of Adhesion Science and Technology 36(12): 1314-1331. https://doi.org/10.1080/01694243.2021.1970318 DOI: https://doi.org/10.1080/01694243.2021.1970318

Centre de Coopération Internationale en Recherche Agronomique pour le Développement. CIRAD. 2023. Les principales caractéristiques technologiques de 245 essences forestières tropicales. CIRAD: Montpellier, Francia. https://tropix.cirad.fr/FichiersComplementaires/FR/Amerique/ITAÚBA%202024.pdf

Delmotte, L.; Ganne-Chedeville, C.; Leban, J.M.; Pizzi, A.; Pichelin, F. 2008. CP-MAS 13C NMR and FT-IR investigation of the degradation reactions of polymer constituents in wood welding. Polymer Degradation and Stability 93(2): 406-412. https://doi.org/10.1016/j.polymdegradstab.2007.11.020 DOI: https://doi.org/10.1016/j.polymdegradstab.2007.11.020

Field, A.; Miles, J.; Field, Z. 2012. Discovering statistics using R. SAGE: London, UK. Ganne-Chedeville, C.; Pizzi, A.; Thomas, A.; Leban, J.M.; Bocquet, J.F.; Despres, A.; Mansouri, H. 2005. Parameter interactions in two-block welding and the wood nail concept in wood dowel welding. Journal of Adhesion Science and Technology 19(13-14): 1157-1174. https://doi.org/10.1163/156856105774429037 DOI: https://doi.org/10.1163/156856105774429037

Instituto de Pesquisas Tecnológicas. IPT. 2023. Informações sobre madeiras. IPT: São Paulo, Brasil. https://madeiras.ipt.br

International Organization for Standardization. ISO. 2017. Physical and mechanical properties of wood - Test methods for small clear wood specimens. ISO 13061-17. ISO: Geneva, Suiza. https://www.iso.org/standard/60079.html

Kanazawa, F.; Pizzi, A.; Properzi, M.; Delmotte, L.; Pichelin, F. 2005. Parameters influencing wood-dowel welding by high-speed rotation. Journal of Adhesion Science and Technology 19(12): 1025-1038. https://doi.org/10.1163/156856105774382444 DOI: https://doi.org/10.1163/156856105774382444

Leban, J.M.; Pizzi, A.; Properzi, M.; Pichelin, F.; Gelhaye, P.; Rose, C. 2005. Wood welding: A challenging alternative to conventional wood gluing. Scandinavian Journal of Forest Research 20(6): 534-538. https://doi.org/10.1080/02827580500432305 DOI: https://doi.org/10.1080/02827580500432305

Li, S.; Zhang, H.; Shu, B.; Cheng, L.; Ju, Z.; Lu, X. 2021. Study on the bonding performance of the Moso bamboo dowel welded to a poplar substrate joint by high-speed rotation. Journal of Renewable Materials 9(7): 1225-1237. https://doi.org/10.32604/jrm.2021.014364 DOI: https://doi.org/10.32604/jrm.2021.014364

Montgomery, D.C.; Runger, G.C. 2003. Applied statistics and probability for engineers. 3rd edition. Wiley: New York, USA. ISBN 9780471204541. 784p.

Pizzi, A.; Leban, J.M.; Kanazawa, F.; Properzi, M.; Pichelin, F. 2004. Wood dowel bonding by high-speed rotation welding. Journal of Adhesion Science and Technology 18(11): 1263-1278. https://doi.org/10.1163/1568561041588192 DOI: https://doi.org/10.1163/1568561041588192

Rodriguez, G.; Diouf, P.; Blanchet, P.; Stevanovic, T. 2010. Wood-dowel bonding by high-speed rotation welding - Application to two Canadian hardwood species. Journal of Adhesion Science and Technology 24(8-10): 1423-1436. https://doi.org/10.1163/016942410X501025 DOI: https://doi.org/10.1163/016942410X501025

Rowell, R.M. 2005. Handbook of wood chemistry and wood composites. CRC Press: Boca Raton, USA. ISBN 9780849315886. 703p. DOI: https://doi.org/10.1201/9780203492437

Smid, P. 2003. CNC Programming Handbook. 3rd edition. Industrial Press Inc.: New York, USA. ISBN 9780831133474. 664p.

Viana, A.C.C. 2023. Soldagem das madeiras de pinus, eucalipto e itaúba por fricção rotativa. Tese de Doutorado. Universidade Federal de Santa Catarina: Florianópolis, Brasil. 187p. https://repositorio.ufsc.br/handle/123456789/251862

Viana, A.C.C.; Moraes, P.D.; Weingaertner, W.L.; Zaniboni, P.A.; Prando, T. 2021. Soldagem das madeiras de pinus e de itaúba por fricção rotativa. Revista Principia 57: 63-75. https://doi.org/10.18265/1517-0306a2021id5809 DOI: https://doi.org/10.18265/1517-0306a2021id5809

Viana, A.C.C.; Ebersbach, F.G.; Moraes, P.D.; Weingaertner, W.L. 2022. Influence of pre-drilling hole and feed rate on welded surface strength of pine-itauba joints. Case Studies in Construction Materials 17.e01473. https://doi.org/10.1016/j.cscm.2022.e01473 DOI: https://doi.org/10.1016/j.cscm.2022.e01473

Viana, A.C.C.; Campos, C.E.M.; Moraes, P.D.; Weingaertner, W.L. 2024. Bond-line strength, chemical properties and cellulose crystallinity of welded pine and itauba wood. Wood Material Science and Engineering 19(1): 56-68. https://doi.org/10.1080/17480272.2023.2225043 DOI: https://doi.org/10.1080/17480272.2023.2225043

Xu, B.-H.; Liu, K.; Zhao, Y.-H.; Bouchaïr, A. 2022. Pullout resistance of densified wood dowel welded by rotation friction. Journal of Materials in Civil Engineering 34(8). e04022177. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004343 DOI: https://doi.org/10.1061/(ASCE)MT.1943-5533.0004343

Zhang, H.; Pizzi, A.; Zhou, X.; Lu, X.; Janin, G. 2014. Comparison of linear vibration welded joints in three different directions of wood tauari (Couratari oblongifilia). International Wood Products Journal 5(4). 228–232. http://dx.doi.org/10.1179/2042645314Y.0000000081 DOI: https://doi.org/10.1179/2042645314Y.0000000081

Zhu, X.; Gao, Y.; Yi, S.; Ni, C.; Zhang, J.; Luo, X. 2017. Mechanics and pyrolysis analyses of rotation welding with pretreated wood dowels. Journal of Wood Science 63: 216–224. https://doi.org/10.1007/s10086-017-1617-4 DOI: https://doi.org/10.1007/s10086-017-1617-4

Župčić, I.; Mihulja, G.; Bogner, A.; Grbac, I.; Hrovat, B. 2008. Welding of solid wood. Drvna Industrija 59(3): 113-119. https://hrcak.srce.hr/en/clanak/46187

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Esta obra está bajo una licencia internacional Creative Commons Atribución 4.0.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.