Cement-bonded wood panels filled with duroplast sanitary ware wastes

DOI:

https://doi.org/10.22320/s0718221x/2025.04Keywords:

Cement-bonded wood panels, duroplast sanitary ware wastes, mechanical properties, morphological properties, physical properties, thermal propertiesAbstract

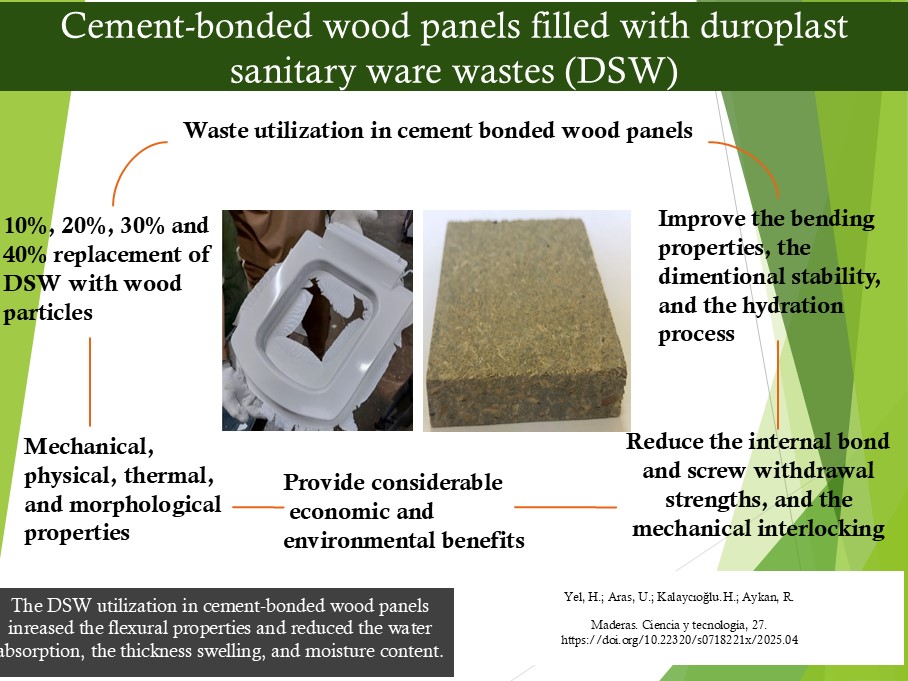

The effect of using duroplast sanitary ware waste as a substitute for wood materials in cement-bonded wood panels was evaluated. Utilizing these wastes can provide considerable economic and environmental benefits by reducing the use of wood materials and the deposits in landfills. Cement-bonded wood panels were produced with the replacement of spruce wood materials by the duroplast sanitary ware waste particles in 10 wt%, 20 wt%, 30 wt%, and 40 wt%. The produced panels were examined in terms of physical, thermal, mechanical, and morphological properties and compared with the related standards. Experimental findings demonstrated that water absorption, moisture content, and thickness swelling values of the panels were enhanced by the addition of duroplast sanitary ware waste. The duroplast sanitary ware waste did not affect the density of the panels. The bending strength and the modulus of elasticity of the cement-bonded wood panels can be increased up to 23 % and 5,6 %, respectively, by the addition of 10 wt% duroplast sanitary ware waste particles. However, the internal bond strength and the screw withdrawal resistance values were reduced by an increment in the use of duroplast sanitary ware waste. The scanning electron microscope observation revealed that there was no mechanical interlocking between the duroplast sanitary ware waste and cement, and the formations of voids in the panels increased with an increase in the duroplast sanitary ware waste particle content. The thermal analysis showed that the use of duroplast sanitary ware waste resulted in increased cement hydration products due to the reduction in the wood content of cement-bonded wood panels.

Downloads

References

Adediran, A.A.; Oladele, I.O.; Omotosho, T.F.; Adesina, O.S.; Olayanju, T.M.A.; Fasemoyin, I.M. 2021. Water absorption, flexural properties and morphological characterization of chicken feather fiber-wood sawdust hybrid reinforced waste paper-cement bio-composites. Materials Today Proceedings 44(1): 2843- 2848. https://doi.org/10.1016/j.matpr.2020.12.1166

ASTM. 2006. Standard test method for evaluating properties of wood-based fiber and particle panel materials. ASTM-D1037. USA.

Amiandamhen, S.O.; Adamopoulos, S.; Adl-Zarrabi, B.; Yin, H.; Norén, J. 2021. Recycling sawmilling wood chips, biomass combustion residues, and tyre fibres into cement-bonded composites: Properties of composites and life cycle analysis. Construction and Building Materials 297. e123781. https://doi.org/10.1016/j.conbuildmat.2021.123781

Akhlaghi, M.A.; Bagherpour, R.; Kalhori, H. 2020. Application of bacterial nanocellulose fibers as reinforcement in cement composites. Construction and Building Materials 241. e118061. https://doi.org/10.1016/j.conbuildmat.2020.118061

Akinyemi, B.A.; Dai, C. 2020. Development of banana fibers and wood bottom ash modified cement mortars.

Construction and Building Materials 241. e118041. https://doi.org/10.1016/j.conbuildmat.2020.118041

Almeida, D.H.; Grillo, R.H.F.; Maestrelli, S.C.; Roveri, C. 2019. Properties of concrete manufactured with use of ceramic sanitary ware waste as aggregate. Revista Materia 24(2). e12350. https://doi.org/10.1590/S1517-707620190002.0665

Aras, U.; Kalaycıoğlu, H.; Yel, H. 2021. The Effect of using pumice powder and plasticizer on physico-mechanical and thermal properties of cement-bonded particleboards. Drvna industrija 72(1): 31-37. https://doi.org/10.5552/drvind.2021.2008

Cao, Y.; Tian, N.; Bahr, D.; Zavattieri, P.D.; Youngblood, J.; Moon, R.J.; Weis, J. 2016. The influence of cellulose nanocrystals on the microstructure of cement paste. Cement and Concrete Composites 74: 164- 173. https://doi.org/10.1016/j.cemconcomp.2016.09.008

Caprai, V.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. 2018. Influence of the spruce strands hygroscopic behaviour on the performances of wood-cement composites. Construction and Building Materials 166: 522-530. https://doi.org/10.1016/j.conbuildmat.2018.01.162

Chen, H.; Qin, R.; Chow, C.L.; Lau, D. 2023. Recycling thermoset plastic waste for manufacturing green cement mortar. Cement and Concrete Composites 137. e104922. https://doi.org/10.1016/j.cemconcomp.2022.104922

Donmez Cavdar, A.; Yel, H.; Boran, S. 2016. Wood cement composites reinforced with polypropylene fibre. Journal of Achievements in Materials and Manufacturing Engineering 76(2): 49-54. https://doi.org/10.5604/17348412.1229478

Donmez Cavdar, A.; Yel, H.; Boran Torun, S. 2022. Microcrystalline cellulose addition effects on the properties of wood cement boards. Journal of Building Engineering 48. e103975. https://doi.org/10.1016/j. jobe.2021.103975

Dweik, H.S.; Ziara, M.M.; Hadidoun, M.S. 2008. Enhancing concrete strength and thermal insulation using thermoset plastic waste. International Journal of Polymeric Materials and Polymeric Biomaterials 57(7): 635-656. http://doi.org/10.1080/00914030701551089

EN. 1993. Wood-based panels, determination of moisture content. EN 322. CEN: Brussels, Belgium.

EN. 1993. Wood-based panels, determination of density. EN 323. CEN: Brussels, Belgium.

EN. 1993. Particlepanels and fiberpanels, determination of swelling in thickness after immersion. EN 317. CEN: Brussels, Belgium.

EN. 1993. Wood-based panels, determination of modulus of elasticity in bending and bending strength. EN 310. CEN: Brussels, Belgium.

EN. 2011. Particleboards and fibreboards, determination of resistance to axial withdrawal of screw. EN 320. CEN: Brussels, Belgium.

EN. 1993. Particlepanels and fiberpanels, determination of tensile strength perpendicular to the plane of the board. EN 319. CEN: Brussels, Belgium.

EN. 2009. Cement-bonded particlepanels - specifications - part 2: Requirements for OPC bonded particlepanels for use in dry, humid, and external conditions. EN 634-2. CEN: Brussels, Belgium.

EN. 1999. Cement-bonded particlepanels- specification- part 1, general requirements. EN 634-1. CEN: Brussels, Belgium.

Farinha, C.; Brito, J.; Veiga, R. 2015. Incorporation of fine sanitary ware aggregates in coating mortars. Construction and Building Materials 83: 194-206. https://doi.org/10.1016/j.conbuildmat.2015.03.028

Fiore, A.; Marano, G.C.; Marti, C.; Molfetta, M. 2014. On the fresh/hardened properties of cement composites incorporating rubber particles from recycled tires. Advances in Civil Engineering 2014. e876158. https://doi.org/10.1155/2014/876158

García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra- Romero, M.I. 2015. Ceramic ware waste as coarse aggregate for structural concrete production. Environmental Technology 36(23): 3050-3059. https://doi.org/10.1080/09593330.2014.951076

Gu, L.; Ozbakkaloglu, T. 2016. Use of recycled plastics in concrete: a critical review. Waste Management 51: 19-42. https://doi.org/10.1016/j.wasman.2016.03.005

Halicka, A.; Ogrodnik, P.; Zegardlo, B. 2013. Using ceramic sanitary ware waste as concrete aggregate. Construction and Building Materials 48: 295-305. http://dx.doi.org/10.1016/j.conbuildmat.2013.06.063

Hansted, F.A.S.; Mantegazini, D.Z.; Ribeiro, T.M.; Gonçalves, C.E.C.; Balestieri, J.A.P. 2023. A mini- review on the use of waste in the production of sustainable Portland cement composites. Waste Management & Research 41(4): 828-838. https://doi.org/10.1177/0734242x221135246

Hermawan, D.; Hata, T.; Umemura, K.; Kawai, S.; Nagadomi, W.; Kuroki, Y. 2001. Rapid production of high-strength cement-bonded particleboard using gaseous or supercritical carbon dioxide. Journal Wood of Science 47: 294-300. http://dx.doi.org/10.1007/BF00766716

Hossain, SkS.; Roy, P.K. 2020. Sustainable ceramics derived from solid wastes: a review. Journal of Asian Ceramic Societies 8(4):984-1009. https://doi.org/10.1080/21870764.2020.1815348

Jin, Y.; Lei, Z.; Taynton, P.; Huang, S.; Zhang, W. 2019. Malleable and recyclable thermosets: the next generation of plastics. Matter 1: 1456-1493. https://doi.org/10.1016/j.matt.2019.09.004

Kazemi, M.; Faisal Kabir, S.; Fini, E.H. 2021. State of the art in recycling waste thermoplastics and thermosets and their applications in construction. Resources, Conservation and Recycling 174. e105776. https://doi.org/10.1016/j.resconrec.2021.105776

Klimek, B.; Szulej, J.; Ogrodnik, P. 2020. The effect of replacing sand with aggregate from sanitary ceramic waste on the durability of stucco mortars. Clean Technologies and Environmental Policy 22: 1929- 1941. https://doi.org/10.1007/s10098-020-01932-w

Khern, Y.C.; Paul, S.C.; Kong, S.Y.; Babafemi, A.J.; Anggraini, V.; Miah, M.J.; Šavija, B. 2020. Impact of chemically treated waste rubber tire aggregates on mechanical, durability and thermal properties of concrete. Frontiers in Materials 7. e90. https://doi.org/10.3389/fmats.2020.00090

Maljaee, H.; Paiva, H.; Madadi, R.; Tarelho, L.A.C.; Morais, M.; Ferreira, V.M. 2021. Effect of cement partial substitution by waste-based biochar in mortars properties. Construction and Building Materials 301. e124074. https://doi.org/10.1016/j.conbuildmat.2021.124074

Marques, B.; Almeida J.; Tadeu, A.; Antonio, J.; Santos, M.I.; Brito, J.; Oliveira, M. 2021. Rice husk cement-based composites for acoustic barriers and thermal insulating layers. Journal of Building Engineering 39. e102297. https://doi.org/10.1016/j.jobe.2021.102297

Mayer, A.K.; Kuqo, A.; Koddenberg, T.; Mai, C. 2022. Seagrass- and wood-based cement boards: A comparative study in terms of physico-mechanical and structural properties. Composites Part A: Applied Science and Manufacturing 156. e106864. https://doi.org/10.1016/j.compositesa.2022.106864

Medina, B.; Juan, A.; Frías, M.; Sánchez de Rojas, M.I., Morán, J.M.; Guerra, M.I. 2011. Characterization of concrete made with recycled aggregate from ceramic sanitary ware. Materiales de Construccion 61 (304): 533-546. https://doi.org/10.3989/mc.2011.59710

Nazerian, M.; Ghalehno, M.D.; Gozali, E. 2011. Effects of wood species, particle sizes and dimensions of residue obtained from trimming of wood-cement composites on physical and mechanical properties of cement-bonded particleboard. Wood Material Science & Engineering 6(4): 196-206. http://dx.doi.org/10.1080/17480272.2011.601816

Negash, Y.T.; Hassan, A.M.; Tseng, M.L.; Wu, K.J.; Ali, M.H. 2021. Sustainable construction and demolition waste management in Somaliland: Regulatory barriers lead to technical and environmental barriers. Journal of Cleaner Production 297. e126717. https://doi.org/10.1016/j.jclepro.2021.126717

Ohijeagbon, I.O.; Adeleke, A.A.; Mustapha, V.T.; Olorunmaiye, J.A.; Okokpujie, I.P.; Ikubanni, P.P. 2020. Development and characterization of wood-polypropylene plastic-cement composite board. Case Studies in Construction Materials 13. e00365. https://doi.org/10.1016/j.cscm.2020.e00365

Ortigara, Y.V.B.; Lintz, R.C.C.; Pimentel, L.L.; Ortigara, M.C.R.S.; Jacintho, A.E.P.G.A.; Gachet, L.A.; Fontanini, P.S.P. 2022. Influence of the use of sanitary ware waste in self-compacting concrete production. Materials Today Proceedings 65(2): 511-519. https://doi.org/10.1016/j.matpr.2022.03.065

Panyakapo, P.; Panyakapo, M. 2008. Reuse of thermosetting plastic waste for lightweight concrete. Waste Management 28(9): 1581-1588. http://doi.org/10.1016/j.wasman.2007.08.006

Raad, D.; Assaad, J.J. 2022. Structural properties of fiber-reinforced concrete containing thermosetting polymer plastic wastes. Journal of Sustainable Cement-Based Materials 11(2): 137-147. http://doi.org/10.108 0/21650373.2021.1899998

Reig, L.; Soriano, L.; Borrachero, M.V.; Monzó, J.M.; Payá, J. 2022. Potential use of ceramic sanitary ware waste as pozzolanic material. Boletín de la Sociedad Española de Cerámica y Vidrio 6(1): 611-621. https://doi.org/10.1016/j.bsecv.2021.05.006

Roushdy, M. 2019. Recycling of sanitary ware wastes and ceramic tiles wastes. LAP LAMBERT Academic Publishing: Saarbrücken, Germany.

Saikia, N.; Brito, J. 2013. Waste Polyethylene Terephthalate as an Aggregate in Concrete. Materials Research 16(2): 341-350. https://doi.org/10.1590/S1516-14392013005000017

Soroushian, P.; Won, J.P.; Hassan, M. 2013. Durability and microstructure analysis of CO2-cured cement-bonded wood particleboard. Cement and Concrete Composites 41: 34-41. http://dx.doi.org/10.1016/j.cemconcomp.2013.04.014

SPSS Statistics. 2020. SPSS software version 21.0. IBM.

Tayeh, B.A.; Almeshal, I.; Magbool, H.M.; Alabduljabbar, H.; Alyousef, R. 2021. Performance of sustainable concrete containing different types of recycled plastic. Journal of Cleaner Production 328: e129517. https://doi.org/10.1016/j.jclepro.2021.129517

Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.S.; Shih, K. 2016. Recycling contaminated wood into eco-friendly particleboard using green cement and carbon dioxide curing. Journal of Cleaner Production 137: 861-870. http://dx.doi.org/10.1016/j.jclepro.2016.07.180

Xing, C.; Zhang, S.Y.; Deng, J.; Riedl, B.; Cloutier, A. 2006. Medium density fiberboard performance as affected by wood fiber acidity, bulk density, and size distribution. Wood Science and Technology 40: 637- 646. https://doi.org/10.1007/s00226-006-0076-7

Yel, H.; Donmez Cavdar, A.; Boran Torun, S. 2020. Effect of press temperature on some properties of cement bonded particleboard. Maderas. Ciencia y Tecnología 22(1): 83-92. https://doi.org/10.4067/S0718-221X2020005000108

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.