Acoustic and performance-based ipe wood selection for violin bows

DOI:

https://doi.org/10.22320/s0718221x/2025.30Keywords:

Bow making, Handroanthus spp, violin bow, wood technology, wood acoustics, musical performance evaluationAbstract

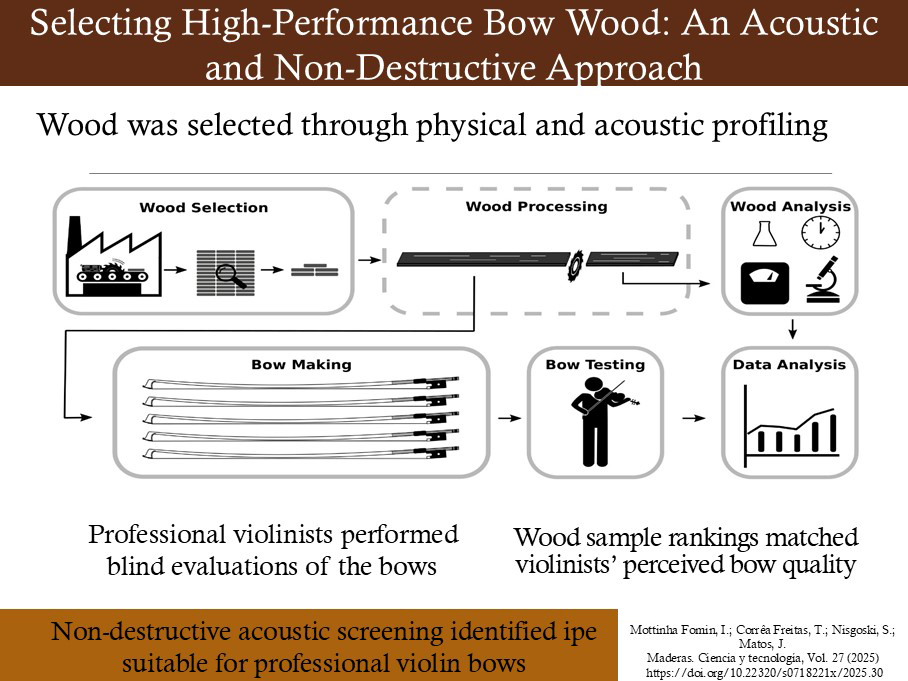

Pernambuco wood is the most used material for making professional violin bows. Since the 18th century, it has been known as the best wood for this purpose. However, it is classified as an endangered species. Some researchers looking for alternative woods for bow making have pointed out that ipe wood may have desirable features for making violin bows. Therefore, the objective of this research was to define an evaluation method that could guide selection steps in order to find suitable wood for violin bows testing it in practice. To carry out this research, ipe wood samples were selected from lumber companies and analyzed. Afterward, five violin bows were made and evaluated by professional violinists using a 6-point scale questionnaire. As a result, ipe bows were highly rated by professional violinists, with mean scores spanning 4.21 to 5.10, suggesting a positive level of acceptance. Furthermore, there was a coherence between the scores given by musicians and the estimated potential quality of wood which also had a larger proportion of fibers and lower apparent density, in conformity with other studies. It was concluded that the method adopted worked to find ipe wood suitable for violin bows with characteristics needed to produce professional violin bows even among piles of discarded wood at lumber companies.

Downloads

References

Alves, E.S.; Longui, E.L.; Amano, E. 2008. Pernambuco wood (Caesalpinia echinata) used in the manufacture of bows for string instruments. IAWA Journal 29(3): 323-335. https://doi.org/10.1163/22941932-90000190 DOI: https://doi.org/10.1163/22941932-90000190

Andrade, V.H.F. 2015. Modelos de crescimento para Hymenaea courbaril L. e Handroanthus serratifolius (Vahl) S.O. Grose em floresta de terra firme utilizando análise de anéis de crescimento. MSc Thesis. Universidade Federal do Paraná. 96p. https://hdl.handle.net/1884/38209

Angyalossy, V.; Amano, E.; Alves, E.S. 2005. Madeiras utilizadas na fabricação de arcos de instrumentos de corda: aspectos anatômicos. Acta Botanica Brasilica 19(4): 819-834. https://doi.org/10.1590/S0102-33062005000400018 DOI: https://doi.org/10.1590/S0102-33062005000400018

Baar, J.; Tippner, J.; Gryc, V. 2012. The influence of wood density on longitudinal wave velocity determined by the ultrasound method in comparison to the resonance longitudinal method. European Journal of Wood and Wood Products 70: 767-769. https://doi.org/10.1007/s00107-011-0550-2 DOI: https://doi.org/10.1007/s00107-011-0550-2

Baar, J.; Tippner, J.; Rademacher, P. 2015. Prediction of mechanical properties - modulus of rupture and modulus of elasticity - of five tropical species by nondestructive methods. Maderas. Ciencia y tecnología 17(2): 239-252. http://dx.doi.org/10.4067/S0718-221X2015005000023 DOI: https://doi.org/10.4067/S0718-221X2015005000023

Boyden, D.D. 2002. The History of Violin Playing from Its Origins to 1761. Oxford University Press: Oxford, United Kingdom.

Bucur, V. 2006. Acoustics of Wood. 2nd edition. Springer: Berlin, Germany. https://doi.org/10.1007/3-540-30594-7 DOI: https://doi.org/10.1007/3-540-30594-7

Caussé, R.; Maigret, J.; Dichtel, C.; Bensoam, J. 2001. Study of violin bow quality. In: Proceedings of the International Symposium On Musical Acoustics. Perugia, Italy. http://articles.ircam.fr/textes/Causse01a/index.pdf

CITES. 2022. Appendices I, II and III. Convention on International Trade in Endangered Species of Wild Fauna and Flora: Switzerland. https://cites.org/sites/default/files/eng/app/2025/E-Appendices-2025-02-07.pdf

COPANT. 1973. Maderas. Método de ensayo de flexión estática. COPANT 555-1973. COPANT: Buenos Aires, Argentina.

Dell’Olio, P. 2009. Violin Bow Construction and Its Influence on Bowing Technique in the Eighteenth and Nineteenth Centuries. PhD Thesis. Florida State University College of Music. https://pt.scribd.com/document/318047701/1-bowing

Fritz, C.; Curtin, J.; Poitevineau, J.; Borsarello, H.; Wollman, I.; Tao, F.-C.; Ghasarossian, T. 2014. Soloist evaluations of six old Italian and six new violins. Proceedings of the National Academy of Sciences of the United States of America 111(20): 7224-7229. https://doi.org/10.1073/pnas.1323367111 DOI: https://doi.org/10.1073/pnas.1323367111

Gough, C.E. 2011. The violin bow: Taper, camber and flexibility. The Journal of the Acoustical Society of America 130(6): 4105-4116. https://doi.org/10.1121/1.3652862 DOI: https://doi.org/10.1121/1.3652862

Guzmán, J.A.S.; Talavera, F.J.F.; Anda, R.R.; Andrade, P.A.T.; Ramírez, M.G.L.; Quirarte, J.R.; Waitkus, C.; Richter, H.G. 2010. Fichas de propiedades tecnológicas y usos de maderas nativas de México e importadas. Amaya Ediciones S DE RL DE CV: Guadalajara, México.

Hori, R.; Müller, M.; Watanabe, U.; Lichtenegger, H.C.; Fratzl, P.; Sugiyama, J. 2002. The importance of seasonal differences in the cellulose microfibril angle in softwoods in determining acoustic properties. Journal of Materials Science 37: 4279-4284. https://doi.org/10.1023/A:1020688132345 DOI: https://doi.org/10.1023/A:1020688132345

Huber, J. 1995. Der Geigenmarkt: ein Führer zum Instrumentenkauf = The violin Market: the violinist’s guide to instrument purchase. Fachbuchreihe Das Musikinstrument; Bd. 59. E. Bochinsky: Frankfurt am Main, Germany.

IAWA. 1989. List of microscopic features for hardwood identification. In: IAWA Bulletin 10(3): 234-329. Wheeler, E.A.; Baas, P.; Gasson, P.E. 4th Printing 2007. https://www.iawa-website.org/uploads/soft/Abstracts/IAWAlistofmicroscopicfeaturesforhardwoodidentification.pdf

InsideWood. 2004. Published on Internet. https://insidewood.lib.ncsu.edu/description?3

Kun, J.; Regh, J. 1994. The Art of Bow Making. Regh-Kun: Wappingers Falls, United States. Google Books. s.f. Información no disponible del libro. https://books.google.com.br/books?id=EZgIAQAAMAAJ Lehmann, E. 2006. Dictionnaire de la Lutherie et de l’archèterie. Les Amis de la Musique: Spa, Belgium.

Longui, E.L. 2009. Potencial de madeiras nativas na fabricação de arcos para instrumentos de corda. PhD Thesis. Instituto de Botânica da Secretaria do Meio Ambiente. São Paulo, Brasil. http://www.dominiopublico.gov.br/pesquisa/DetalheObraForm.do?select_action=&co_obra=15808

Longui, E.L.; Yojo, T.; Lombardi, D.R.; Alves, E.S. 2010a. The potential of ipê (Handroanthus spp.) and maçaranduba (Manilkara spp.) woods in the manufacture of bows for string instruments. IAWA Journal 31(2): 149-160. https://doi.org/10.1163/22941932-90000012 DOI: https://doi.org/10.1163/22941932-90000012

Longui, E.L.; Lombardi, D.R.; Alves, E.S. 2010b. Potential Brazilian wood species for bows of string instruments. Holzforschung 64: 511-520. https://doi.org/10.1515/hf.2010.068 DOI: https://doi.org/10.1515/hf.2010.068

Macedo, T.M.; Costa, C.G.; Lima, H.C.; Barros, C.F. 2020. Wood anatomy of historic French violinbows made of pernambuco wood. IAWA Journal 41(3): 320-332. https://doi.org/10.1163/22941932-bja10011 DOI: https://doi.org/10.1163/22941932-bja10011

Mainieri, C.; Chimelo, J.P. 1989. Ficha de características das madeiras brasileiras. 2nd edition. Instituto de Pesquisas Tecnológicas - IPT: São Paulo, Brasil.

Matsunaga, M. 2000. Aptitude of pernambuco (Guilandina echinata Spreng.) as a violin bow and role of its extractives on the vibrational property. PhD Thesis. Kyoto University. Kyoto, Japan. https://repository.kulib.kyoto-u.ac.jp/dspace/handle/2433/157139?mode=full

McLennan, J.E. 1990. An evaluation of the Giovanni Lucchi Elasticity Tester. Journal of the American Musical Instrument Society 9(1): 38. https://newt.phys.unsw.edu.au/music/publications/mclennan/lucchi.pdf

MMA Brasil. 2014. Portaria n. 443 de dezembro de 2014. Sobre reconhecimento como espécies da flora brasileira ameaçadas de extinção aquelas constantes da “Lista Nacional Oficial de Espécies da Flora Ameaçadas de Extinção”. Diário Oficial da União: Brasília. https://ckan.jbrj.gov.br/dataset/portaria_443/resource/8d-0bbe11-e7d4-49c3-98ba-c07f2dfacf5e

Pace, M.R.; Lohmann, L.G.; Olmstead, R.G.; Angyalossy, V. 2015. Wood anatomy of major Bignoniaceae clades. Plant Systematics and Evolution 301: 967-995. https://doi.org/10.1007/s00606-014-1129-2 DOI: https://doi.org/10.1007/s00606-014-1129-2

Portal-Cahuana, L.A.; Latorraca, J.V.F.; Camargo-Pace, J.H.; Santos, G.C.V.; Oliveira-Lima, D.; Alves-Ramos, L.M.; Carmo, J.F.D. 2019. Variabilidad radial física y anatómica del leño de árboles de Amburana cearensis (allemao) A.C.Sm. Colombia Forestal 22(1): 17-26. https://doi.org/10.14483/2256201X.13083 DOI: https://doi.org/10.14483/2256201X.13083

Robson, C. 1993. Real World Research. Blackwell Publishers: Oxford, United Kingdom; Malden, United States.

Schimleck, L.R.; Espey, C.; Mora, C.R.; Evans, R.; Taylor, A.; Muñiz, G. 2009. Characterization of the wood quality of pernambuco (Caesalpinia echinata Lam.) by measurements of density, extractives content, microfibril angle, stiffness, color, and NIR spectroscopy. Holzforschung 63: 457-463. https://doi.org/10.1515/HF.2009.082 DOI: https://doi.org/10.1515/HF.2009.082

Schimleck, L.R.; Matos, J.L.M.; Oliveira, J.T.S.; Muñiz, G.I.B. 2011. Non-destructive estimation of pernambuco (Caesalpinia echinata) clear wood properties using near infrared spectroscopy. Journal of Near Infrared Spectroscopy 19: 411-419. https://doi.org/10.1255/jnirs.953 DOI: https://doi.org/10.1255/jnirs.953

Simpson, W.T. 1998. Relationship between speed of sound and moisture content of red oak and hard maple during drying. Wood and Fiber Science 30: 405-413. https://wfs.swst.org/index.php/wfs/article/download/838/838

Wegst, U.G.K. 2006. Wood for sound. American Journal of Botany 93(10): 1439-1448. https://doi.org/10.3732/ajb.93.10.1439 DOI: https://doi.org/10.3732/ajb.93.10.1439

Wegst, U.G.K.; Oberhoff, S.; Weller, M.; Ashby, M.F. 2007. Materials for violin bows. International Journal of Materials Research 98: 1230-1237. https://doi.org/10.3139/146.101580 DOI: https://doi.org/10.3139/146.101580

Wheeler, E.A. 2011. InsideWood - A web resource for hardwood identification. IAWA Journal 32(2): 199-211. https://doi.org/10.1163/22941932-90000051 DOI: https://doi.org/10.1163/22941932-90000051

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.