Moisture-induced elastic constants of poplar

DOI:

https://doi.org/10.22320/s0718221x/2025.32Keywords:

Elasticity modulus, shear modulus, Poisson’s ratio, Populus x canadensis, ultrasonic testing, nondestructive evaluation, wood anisotropyAbstract

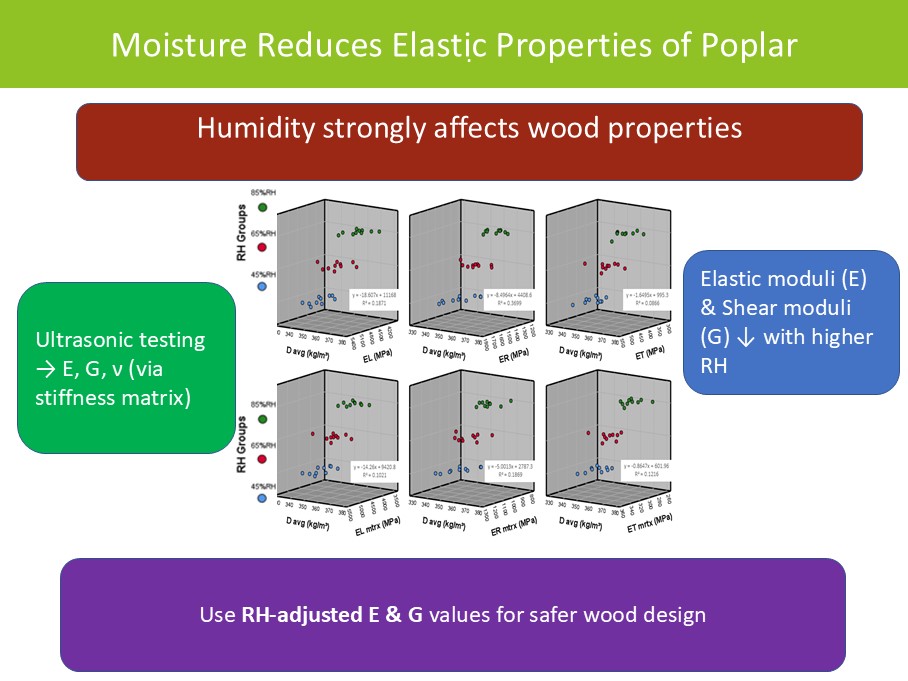

Twelve elastic constants of Populus × canadensis, previously unavailable in the literature, were determined using ultrasonic testing.Samples were conditioned at a temperature of 20 °C ± 1 °C and 45 %, 65 %, and 85 % relative humidity. An Olympus EPOCH 650 flaw detector was used with V153-RM (1 MHz shear wave), and A133S-RM (2,25 MHz pressure wave) contact transducers. A contact medium was applied. Wave propagation times were measured along the principal directions (L, R, T), the main planes (LR, LT, RT, RL, TL, TR), and the off-axis planes (LR45°, LT45°, RT45°). Ultrasonic wave velocities were calculated across the specified directions and planes. These velocities were then used to estimate moduli (EL, ER, ET, GLR, GLT, GRT) and Poisson’s ratios (µLR, µLT, µRT, µRL, µTL, µTR) via stiffness matrix analysis. Moduli were also calculated using a simple formula multiplying the density and velocity for comparison. Elastic moduli derived from the stiffness matrix were substantially lower than those from the simple density–velocity formula, while shear moduli remained nearly identical. Both moduli steadily decreased with the increase in moisture content. Moisture content significantly affected all moduli. In contrast, Poisson’s ratios showed no consistent trend with moisture. Specifically, µLR and µRL increased linearly with moisture, while the other ratios decreased irregularly. For µRT, the effect of moisture was insignificant. Relationships between density and velocity, moduli, and Poisson’s ratios were assessed using coefficients of determination.The coefficients ranged from 0,23 to 0,56 for velocities, 0,08 to 0,37 for elasticity, 0,23 to 0,31 for shear, and 0 to 0,10 for ratios. When the coefficient was calculated within the humidity groups significant increases were observed. It was assumed that water-related increases in density did not reflect structural solidification, and therefore did not lead to improved elasric properties. This effect is explained by the well-known reduction in wave velocities caused by water, which dominates the calculations.

Downloads

References

Aydın, M.; Yılmaz Aydın, T. 2020. Moisture dependent elastic properties of naturally aged black pine wood. Construction and Building Materials 260. e120752. https://doi.org/10.1016/j.conbuildmat.2020.120752 DOI: https://doi.org/10.1016/j.conbuildmat.2020.120752

Aydın, M.; Yılmaz Aydın, T. 2023. Influence of growth ring number and width on elastic constants of poplar. Bioresources 18(4): 8484-8502. https://doi.org/10.15376/biores.18.4.8484-8502 DOI: https://doi.org/10.15376/biores.18.4.8484-8502

Aydın, S.; Yardımcı, M.Y.; Ramyar, K. 2007. Mechanical properties of four timber species commonly used in Turkey. Turkish Journal of Engineering and Environmental Sciences 31(1): 19-27. https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=338918c30b6265523cb2dc476b43655c6f255537

Baar, J.; Tippner, J.; Rademacher, P. 2015. Prediction of mechanical properties - modulus of rupture and modulus of elasticity - of five tropical species by nondestructive methods. Maderas. Ciencia y tecnología 17(2): 239-252. https://doi.org/10.4067/S0718-221X2015005000023 DOI: https://doi.org/10.4067/S0718-221X2015005000023

Bachtiar, E.V.; Sanabria, S.J.; Mittig, J.P.; Niemz, P. 2017. Moisture-dependent elastic characteristics of walnut and cherry wood by means of mechanical and ultrasonic test incorporating three different ultrasound data evaluation techniques. Wood Science and Technology 51(1): 47-67. https://doi.org/10.1007/s00226-016-0851-z DOI: https://doi.org/10.1007/s00226-016-0851-z

Burubai, W.; Amula, E.; Davies, R.M.; Etekpe, G.W.W.; Daworiye, S.P. 2008. Determination of Poisson’s ratio and elastic modulus of African nutmeg (Monodora myristica). International Agrophysics 22: 99-102. https://bibliotekanauki.pl/articles/25936.pdf

Casado, M.; Acuña, L.; Vecilla, D.; Relea, E.; Basterra, A.; Ramón, G.; López, G. 2010. The influence of size in predicting the elastic modulus of Populus x euramericana timber using vibration techniques. In: Structures and Architecture. Sousa Cruz, P.J. (Ed.). CRC Press: London, United Kingdom. https://maderas.uva.es/files/2019/03/2010-Casado-et-al-The-influence-of-size-MOE-Populus-PLG.pdf DOI: https://doi.org/10.1201/b10428-282

Ettelaei, A.; Layeghi, M.; Zarea Hosseinabadi, H.; Ebrahimi, G. 2019. Prediction of modulus of elasticity of poplar wood using ultrasonic technique by applying empirical correction factors. Measurement 135: 392–399. https://doi.org/10.1016/j.measurement.2018.11.076 DOI: https://doi.org/10.1016/j.measurement.2018.11.076

Fu, W.-L.; Guan, H.-Y.; Kei, S. 2021. Effects of moisture content and grain direction on the elastic properties of Beech wood based on experiment and finite element method. Forests 12(5): 610. https://doi.org/10.3390/f12050610 DOI: https://doi.org/10.3390/f12050610

Gonçalves, R.; Trinca, A.J.; Pellis, B.P. 2014. Elastic constants of wood determined by ultrasound using three geometries of specimens. Wood Science and Technology 48(2): 269–287. https://doi.org/10.1007/s00226-013-0598-8 DOI: https://doi.org/10.1007/s00226-013-0598-8

Gray, J.D.; Grushecky, S.T.; Armstrong, J.P. 2008. Stress wave velocity and dynamic modulus of elasticity of yellow-poplar ranging from 100 to 10 percent moisture content. In: Proceedings of the 16th Central Hardwoods Forest Conference, Douglass, F.J.; Michler, C.H. (Eds.). USDA Forest Service: West Lafayette, IN, USA, pp. 139–142. https://www.fs.usda.gov/nrs/pubs/gtr/gtr_nrs-p-24.pdf

Güntekin, E.; Aydin, T.Y.; Niemz, P. 2016a. Some orthotropic elastic properties of Fagus orientalis as influenced by moisture content. Wood Research 61(1): 95–104. DOI: https://doi.org/10.31195/ejejfs.258624

Güntekin, E.; Aydin, T.Y.; Niemz, P. 2016b. Some orthotropic mechanical properties of Sessile oak (Quercus petrea) as influenced by moisture content. Eurasian Journal of Forest Science 4(1): 40–47. https://doi.org/10.31195/EJEJFS.258624 DOI: https://doi.org/10.31195/ejejfs.258624

Guo, H.; Xu, C.; Lin, L.; Wang, Q.; Fu, F. 2011. The composite wood by poplar wood impregnated with Na2SiO3-polyacrylamide hybrid solution. Science and Engineering of Composite Materials 18(3): 151–155. https://doi.org/10.1515/secm.2011.025 DOI: https://doi.org/10.1515/secm.2011.025

Gómez-Royuela, J.L.; Majano-Majano, A.; Lara-Bocanegra, A.J.; Reynolds, T.P.S. 2021. Determination of the elastic constants of thermally modified beech by ultrasound and static tests coupled with 3D digital image correlation. Construction and Building Materials 302. e124270. https://doi.org/10.1016/j.conbuildmat.2021.124270 DOI: https://doi.org/10.1016/j.conbuildmat.2021.124270

Hein, P.R.G.; Silva, J.R.M.; Brancheriau, L. 2013. Correlations among microfibril angle, density, modulus of elasticity, modulus of rupture and shrinkage in 6-year-old Eucalyptus urophylla × E. grandis. Maderas. Ciencia y tecnología 15(2): 171–182. https://doi.org/10.4067/S0718-221X2013005000014 DOI: https://doi.org/10.4067/S0718-221X2013005000014

Hering, S.; Keunecke, D.; Niemz, P. 2012. Moisture-dependent orthotropic elasticity of beech wood. Wood Science and Technology 46(5): 927–938. https://doi.org/10.1007/s00226-011-0449-4 DOI: https://doi.org/10.1007/s00226-011-0449-4

Hodousek, M.; Dias, A.M.P.G.; Martins, C.; Marques, A.; Böhm, M. 2017. Comparison of non-destructive methods based on natural frequency for determining the modulus of elasticity of Cupressus lusitanica and Populus x canadensis. Bioresources 12(1): 270–282. https://doi.org/10.15376/biores.12.1.270-282 DOI: https://doi.org/10.15376/biores.12.1.270-282

Huang, C.; Gong, M.; Chui, Y.; Chan, F. 2020. Mechanical behaviour of wood compressed in radial direction-part I. New method of determining the yield stress of wood on the stress strain curve. Journal of Bioresources and Bioproducts 5(3): 186–195. https://doi.org/10.1016/j.jobab.2020.07.004 DOI: https://doi.org/10.1016/j.jobab.2020.07.004

Izekor, D.N.; Fuwape, J.A.; Oluyege, A.O. 2010. Effects of density on variations in the mechanical properties of plantation grown Tectona grandis wood. Archives of Applied Science Research 2(6): 113–120. https://www.cabidigitallibrary.org/doi/full/10.5555/20113036718

Jiang, J.; Bachtiar, E.V.; Lu, J.; Niemz, P. 2017. Moisture-dependent orthotropic elasticity and strength properties of Chinese fir wood. European Journal of Wood and Wood Products 75(6): 927–938. https://doi.org/10.1007/s00107-017-1166-y DOI: https://doi.org/10.1007/s00107-017-1166-y

Kaymakci, A.; Bayram, B.Ç. 2021. Evaluation of heat treatment parameters’ effect on some physical and mechanical properties of poplar wood with multi-criteria decision making techniques. Bioresources 16(3): 4693–4703. https://doi.org/10.15376/biores.16.3.4693-4703 DOI: https://doi.org/10.15376/biores.16.3.4693-4703

Keunecke, D.; Märki, C.; Niemz, P. 2007. Structural and mechanical properties of yew wood. Wood Research 52(2): 23–38. https://www.cabidigitallibrary.org/doi/full/10.5555/20073297490

Kiaei, M.; Farsi, M. 2016. Vertical variation of density, flexural strength and stiffness of Persian silk wood. Madera y Bosques 22(1): 169–175. https://www.scielo.org.mx/scielo.php?pid=S1405-04712016000100169&script=sci_arttext DOI: https://doi.org/10.21829/myb.2016.221484

Kretschmann, D.E. 2010. Chapter 5. Mechanical properties of wood. In: Wood Handbook Wood as an Engineering Material. Ross, R.J. (Ed.). USDA Forest Product Laboratory: Madison, WI, USA. https://www.fpl.fs.usda.gov/documnts/fplgtr/fpl_gtr190.pdf

Lu, H.; Lian, H.; Xu, J.; Ma, N.; Zhou, Z.; Song, Y.; Yu, Y.; Zhang, X. 2022. Study on the variation pattern and influencing factors of Poisson’s ratio of bamboo. Frontiers in Materials 9. e896756. https://doi.org/10.3389/fmats.2022.896756 DOI: https://doi.org/10.3389/fmats.2022.896756

Miyoshi, Y.; Kojiro, K.; Furuta, Y. 2018. Effects of density and anatomical feature on mechanical properties of various wood species in lateral tension. Journal of Wood Science 64(5): 509–514. https://doi.org/10.1007/s10086-018-1730-z DOI: https://doi.org/10.1007/s10086-018-1730-z

Mizutani, M.; Ando, K. 2014. Influence of a wide range of moisture contents on the Poisson’s ratio of wood. Journal of Wood Science 61(1): 81–85. https://doi.org/10.1007/s10086-014-1438-7 DOI: https://doi.org/10.1007/s10086-014-1438-7

Monteiro, S.R.S.; Martins, C.E.J.; Dias, A.M.P.G.; Cruz, H. 2019. Mechanical characterization of clear wood from Portuguese poplar. Bioresources 14(4): 9677–9685. https://doi.org/10.15376/biores.14.4.9677-9685 DOI: https://doi.org/10.15376/biores.14.4.9677-9685

Murthy, N.; Upadhyay, V.K.; Kushwaha, P.K.; Mohanty, B.N. 2017. Study on anatomical and mechanical properties of plantation grown Melia dubia and Populus deltoides and its suitability for plywood manufacturing. International Journal of Engineering and Technical Research 7(5): 211–214. https://erpublication.org/published_paper/IJETR2220.pdf

Obara, P. 2018. Verification of orthotropic model of wood. Archives of Civil Engineering 64(3): 31–44. https://doi.org/10.2478/ace-2018-0027 DOI: https://doi.org/10.2478/ace-2018-0027

Oliveira, F.G.R.; Sales, A. 2006. Relationship between density and ultrasonic velocity in Brazilian tropical woods. Bioresource Technology 97(18): 2443–2446. https://doi.org/10.1016/j.biortech.2005.04.050 DOI: https://doi.org/10.1016/j.biortech.2005.04.050

Ozyhar, T.; Hering, S.; Sanabria, S.J.; Niemz, P. 2013. Determining moisture-dependent elastic characteristics of beech wood by means of ultrasonic waves. Wood Science and Technology 47(2): 329–341. https://doi.org/10.1007/s00226-012-0499-2 DOI: https://doi.org/10.1007/s00226-012-0499-2

Papandrea, S.F.; Cataldo, M.F.; Bernardi, B.; Zimbalatti, G.; Proto, A.R. 2022. The predictive accuracy of modulus of elasticity (MOE) in the wood of standing trees and logs. Forests 13(8): e1273. https://doi.org/10.3390/f13081273 DOI: https://doi.org/10.3390/f13081273

Pierre, F.; Almeida, G.; Huber, F.; Jacquin, P.; Perré, P. 2013. An original impact device for biomass characterisation: results obtained for spruce and poplar at different moisture contents. Wood Science and Technology 47(3): 537–555. https://doi.org/10.1007/s00226-012-0512-9 DOI: https://doi.org/10.1007/s00226-012-0512-9

Puszyński, J.; Moliński, W.; Preis, A. 2015. The effect of wood on the sound quality of electric string instruments. Acta Physica Polonica A 127(1): 114–116. https://doi.org/10.12693/APhysPolA.127.114 DOI: https://doi.org/10.12693/APhysPolA.127.114

Roohnia, M.; Yavari, A.; Tajdini, A. 2010. Elastic parameters of poplar wood with end cracks. Annals of Forest Science 67(4): 409. https://doi.org/10.1051/forest/2009129 DOI: https://doi.org/10.1051/forest/2009129

Sliker, A.; Yu, Y. 1993. Elastic constants for hardwoods measured from plate and tension tests. Wood and Fiber Science 25(1): 8–22. https://wfs.swst.org/index.php/wfs/article/view/648/648

Sözbir, G.D.; Bektaş, I.; Ak, A.K. 2019. Influence of combined heat treatment and densification on mechanical properties of poplar wood. Maderas. Ciencia y tecnología 21(4): 481–492. https://doi.org/10.4067/S0718-221X2019005000405 DOI: https://doi.org/10.4067/S0718-221X2019005000405

Turkish Standards Institution. 2021. Physical and mechanical properties of wood – Test methods for small clear wood specimens - Part 2: Determination of density for physical and mechanical tests. TS ISO 13061-2. TSE: Ankara, Türkiye.

Vázquez, C.; Gonçalves, R.; Bertoldo, C.; Baño, V.; Vega, A.; Crespo, J.; Guaita, M. 2015. Determination of the mechanical properties of Castanea sativa Mill. using ultrasonic wave propagation and comparison with static compression and bending methods. Wood Science and Technology 49(3): 607–622. https://doi.org/10.1007/s00226-015-0719-7 DOI: https://doi.org/10.1007/s00226-015-0719-7

Villasante, A.; Vignote, S.; Fernandez-Serrano, A.; Laina, R. 2022. Simultaneous treatment with oil heat and densification on physical properties of Populus × Canadensis wood. Maderas. Ciencia y tecnología 24(5): 1–12. https://doi.org/10.4067/S0718-221X2022000100405 DOI: https://doi.org/10.4067/S0718-221X2022000100405

Winter, K.; Maderebner, R.; Dietsch, P. 2023. A new approach to determine and evaluate the Poisson’s ratio of wood. In: Proceedings of the World Conference on Timber Engineering (WCTE 2023), pp. 366–375. Oslo, Norway. https://doi.org/10.52202/069179-0050 DOI: https://doi.org/10.52202/069179-0050

Yılmaz-Aydın, T. 2022. Temperature Influenced Anisotropic Elastic Parameters of Red Pine. Russian Journal of Nondestructive Testing 58(7): 548–562. https://doi.org/10.1134/S1061830922070099 DOI: https://doi.org/10.1134/S1061830922070099

Yılmaz-Aydın, T.; Aydın, M. 2018a. Effect of density and propagation length on ultrasonic longitudinal wave velocity in some important wood species grown in Turkey. Turkish Journal of Forestry 19(4): 413–418. https://doi.org/10.18182/tjf.459005 DOI: https://doi.org/10.18182/tjf.459005

Yılmaz-Aydın, T.; Aydın, M. 2018b. Prediction of bending properties of oriental beech wood exposed to temperature. In: Proceedings of the International Forest Products Congress, pp. 772–778. Karadeniz Technical University: Trabzon, Türkiye.

Yılmaz-Aydın, T.; Aydın, M. 2018c. Relationship between density or propagation length and ultrasonic wave velocity in cedar (Cedrus libani) wood. In: Proceedings of the International Science and Technology Conference, pp. 531–535. Paris, France.

Yılmaz-Aydın, T.; Aydın, M. 2018d. Relationship between density or propagation length and ultrasonic wave velocity in sessile oak (Quercus petraea) wood. In: Proceedings of the 4th International Conference on Advances in Mechanical Engineering, pp. 1708–1712. Yıldız Technical University: İstanbul, Türkiye.

Yılmaz-Aydın, T.; Küçükkose, A. 2020. Ultrasonic testing and evaluation of moisture dependent elastic properties of fir wood. Materials Testing 62(10): 1059–1064. https://doi.org/10.3139/120.111585 DOI: https://doi.org/10.1515/mt-2020-621016

Yılmaz-Aydın, T.; Ozveren, A. 2019. Effects of moisture content on elastic constants of fir wood. European Journal of Wood and Wood Products 77(1): 63–70. https://doi.org/10.1007/s00107-018-1363-3 DOI: https://doi.org/10.1007/s00107-018-1363-3

Zahedi, M.; Kazemi Najafi, S.; Füssl, J.; Elyasi, M. 2022. Determining elastic constants of poplar wood (Populus deltoides) by ultrasonic waves and its application in the finite element analysis. Wood Material Science and Engineering 17(6): 668–678. https://doi.org/10.1080/17480272.2021.1925962 DOI: https://doi.org/10.1080/17480272.2021.1925962

Zhang, Y.; Feng, D.; Dou, Y. 2017. Wood physical and mechanical properties of Populus × canadensis MOEnch and Populus × euramericana (Dode) Guinier cv. Gelrica. Agricultural Sciences and Technology 18(12): 2532–2535. https://www.proquest.com/openview/a4ed5944837f8816c3294538e9a8663e/1?cbl=1596357&pq-origsite=gscholar

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de Reconocimiento de Creative Commons CC-BY que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación esta revista.